|

|

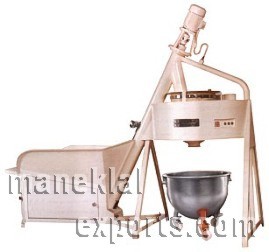

| Auto Flour Sifter |

|

- The sifting machine is ideal

for fast economical sieving of flour for bakeries, chemical and related

products and Pharmaceutical plants. - The machine airs and sieves the flour - Can be used by manually operated or semi-automatic bakeries - A rotating feeder throws the flour into a horizontal conveying system to a vertical conveying screw - The sifting drum loosens the flour which is then fed into the mixing bowl - The bowl of Dough Kneader / High Speed Mixer / Spiral Mixer has to be kept under the machine. The flour will fall into the bowl after being sieved through the Stainless Steel wire mesh. - The machine is constructed on M.S. angle frame covered with M.S. sheet and duly painted. Flour sieving attachment is fitted with steel cams on ball bearings ad oil seals to avoid sound and vibration. - 24 Hours working capacity - Large hopper provided with capacity of one bag of 90 kgs. flour per batch - Simple to use with special demountable stainless steel sieve design incorporating easily replaceable mesh which is automatically correctly tensioned. - Uniformity of flow could be well adjusted and controlled by the feed controller. |

| SPECIFICATIONS:

Capacity: One bag of 90 kg. flour in 5 to 8

minutes |

|

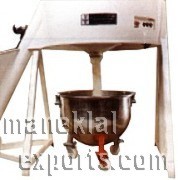

| Water Batching Tank |

|

- The water metering unit

measures the right quantity of water for dough making - The supply of water is as prescribed in the recipe norms the and this ensures uniform product quality - The 65 Liters capacity Water Measuring Unit measures the water to the required quantity for perfect mixing - Water Batching Tank is recomended for kneading best quality dough - The stainless steel tank with double jackets is injected with puff insulation. - An 'empty' and 'full' indicator for water level is provided - Any liquid item can be measured in the measuring unit - The float in the water level gauge indicated the water level on the scale - Machine is provided with electronic control panel and dial temperature meter with built-in safety devices - Water container has a litre scale and a dial temperature meter - Stainless steel valves and solenoid valves provided for water inlet / outlet SPECIFICATIONS: |

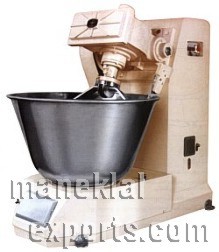

| Spiral Mixer |

|

- The spiral mixer ensures

a fast yet gentle development of dough. - Specially designed agitator synchronized with bowl rotation alternates kneading and resting periods, thus maintaining low dough temperatures - Position of the Centre bar spiral with the bowl and synchronization of spiral turn between the spiral arm and the bowl ensures a superior mix and a homogenous and oxygenated dough - In the 1st phase, the spiral arm and the bowl turn at a low speed so that the ingredients mix homogenously. It is possible to reverse the motion of the bowl - The machine can be manually or automatically (with timers) be set to the second phase. Automatic stopping at the end of the cycle is also possible. Selector switch is fitted for revolving the bowl in clockwise or anticlockwise directions - The machine also has a commutator which permits automatic cycle to work only in the 1st or the 2nd phase. - On wheel locking system with anti-vibration plugs - Separate motors for bowl and spiral - Accident prevention safety shield |

SPECIFICATIONS

|

|

| High Speed Mixer |

|

- The high speed mixer is

designed to mix any kind of dough for mass production of Bread, Buns,

Pizzas, Rusks, etc. - The mixing arm motion gently mixes and kneads the dough for highest development, maximum water absorption and excellent aeration to give baked goods improved flavour with excellent texture. - Easily removable Stainless Steel bowls for increased production - It requires chilled water (at 2 to 4 degree celcius) - The dough becomes light and airy, facilitating instant inflation of dough in a period of 2 to 3 minutes of mixing and the dough is ready for further process - Switches are provided with timers. On completion of the prefixed time, the mixing operation gets disengaged - 24 Hours working capacity - Mixing time - 2 to 3 minutes - Fermentation period NIL - Supplied with 2 bowls (One fitted and one extra) |

SPECIFICATIONS

|

|

| Dough Kneader |

|

- A rotary type machine that can

be used for kneading dough for making bread, buns, rusks, pizza base, etc. - Machine fitted with gearbox to synchronize speed of the kneader arm and bowl for perfect mixing of dough - Machine supplied with Stainless Steel Bowl and Kneading Arm. - All moving parts on Ball Bearings for soundless and smooth operation - 24 hours working capacity |

SPECIFICATIONS

|

|

| Dough Hoist |

|

- Ideal for removable bowls to

be directly tipped into Dough Divider - Three different dumping directions possible: to the left, to the right or tilting overhead - Available as stationary or movable units - After mixing the dough in the bowl, the same bowl of the mixers is to be fitted to the hoist - Machine is constructed of M. S. thick plates and has a robust construction - 24 Hour working capacity - Self acting safety locking mechanism to prevent slipping out of bowl - Bowl receiver can be made to fit High Speed Mixer - Variable tilting height - Fitted with safety stop and limit switch |

| SPECIFICATIONS Tilting Capacity: 100 kgs P/C Motor: 1 HP Weight: 1350 kgs. Ceiling Height: 14 Feet (4.3 m) Dimensions: 2.00 x 1.25 x 2.50 m |

|

| Dough Divider |

|

- The machine can be sued

for all types of dough and is fitted with two standard dividing pistons - The dough hopper can be fitted manually or with lifting / tilting device depending on the production required - The machine can be used either for manual removal of dough pieces or in the semi-automatic bread plant - The divider works on rotating drum principal. The measuring pistons move in rotating drums. - Dough pieces are ejected by gravitational force - The amount of dough conveyed can be adjusted to the required weight to the required weight by means of handwheel - The dough reaches the dividing chamber from the hopper. After the chamber has been closed by the knife, the dough is conveyed into the measuring chamber by the main piston - The volume of this measuring chamber corresponds to the set dough weight - After the rotating drum has turned 90 degrees, the dough piece is pushed out by measuring piston. As the rotating drum moves back, the dough piece is scraped off and drops onto the discharge conveyor. - Two pocket dividing unit producing two pieces of dough - Hand wheel for adjustment of weight volume - Hand wheel for the production speed adjustment (minimum / maximum) cuttings/ minute - Stainless steel hopper with 80 kgs. dough capacity |

| SPECIFICATIONS: Capacity: 1800 pcs per hour of 200 gms. to 1000 gms. Motor: 3 HP Weight: 850 kgs. Dimensions: 2.00 x 1.70 x 1.60 m |

|

| Dough Rounder |

|

- The Conical Dough Rounder's

rounding Trough gently rounds dough pieces into uniform dough balls,

perfectly sealed with a thin skin. - Machine is designed with a rotating cone and spiral aluminium tracks around it - The rounder could be connected to a Dough Divider on the input side and a First Proover on the output side - The Dough Divider would divide the dough into pieces as per their weight (but in uneven shapes). These could be dropped into the Dough Rounder through conveyor - The dough pieces move from bottom to top in the tracks that are designed to give the finished pieces a good shape with a right tension - After rounding, the dough will automatically step out to reach the First Proover - The cone has ridges and the aluminium rounding tracks are adjustable - A built-in cold air blower is provided which prevents the dough pieces from sticking with each other - All moving parts have ball bearings and castor for transportation - 24 Hours working capacity - Dough weight range from 400 to 800 gms - Built-in automatic flour dusting device (adjustable) |

| SPECIFICATIONS: Capacity: 1800 Loaves per Hour Motor: 3 HP Weight: 750 kgs. Dimensions: 1.10 x 1.10 x 1.60 m |

|

| First Proover |

|

- The First Proover could

be added to automate the line - It is designed for rounded dough pieces and moves upwards step by step matching the speed of the Dough Rounder - It receives the rounded dough from the Dough Rounder. The dough passes through a prep loader for proper positioning in the Proover - It gives uniform prooving and discharges the dough into the moulder - Dough pieces turn over 6 times during the cycle. This ensuressuperior loaf quality and even fermentation - It is covered with acrylic sheets for dust prevention - All rollers are on ball bearings - All contact parts are nickel and chrome plated - Good quality cotton belts are used - It is driven by a gear box, giving a low and fixed speed - Total running length of the dough is 40 to 50 feets - Prooving can be adjusted from 1.5 to 2.5 m |

| SPECIFICATIONS: Capacity: 1800 Loaves per Hour Motor: Two 1 HP each Weight: 750 gms Dimensions: 6.10 x 1.00 x 4.00 m Note: The photograph above shows the Dough Moulder attached below the First Proover. This machine is to be procured separately. |

|

| Dough Moulder |

|

- The Dough Moulder is

ideally suited for production of most varieties of Bread in small and

medium sized bakeries - The dough pieces are divided (in the Dough Divider) and passed to the Dough Rounder. The rounded dough is to be fed to the Dough Moulder manually or through First Proover. The dough is flattened by the adjustable stainless steel rollers of the Dough Moulder and coiled up by a chain drag, pre-moulded by a spring loaded sun-mica laminated pressure board. The pressure board is adjusted by hand levers. - The roller gap is adjustable brom 8 to 20 mm. The mouldng loaf length is from 350 to 400 mm for dough pieces of 400 to 800 gms. Built-in cold air blower prevents the pieces from sticking - All moving parts are on ball bearings, Stainless steel rollers are fitted with individual spring loaded teflon scraper, all contact parts are nickel and chrome plated - A removable receiving stainless steel plate is installed to collect the loaves - 3 Pairs of Squeeze rollers of Stainless Steel provided |

| SPECIFICATIONS: Capacity: 1800 Loaves per Hour Motor: 2 HP Weight: 950 kgs. Dimensions: 3.10 x 0.80 x 1.70 m |

|

| Electric Deck Oven |

|

- Multipurpose Industrial Oven

for baking Breads, Buns, Rusks, Cakes, Biscuits, Pizza Bases and other

bakery products - Available in different capacities. Double decks also available - Front is of Stainless Steel 304. - Casing of thick M.S. Sheets and heavy angles and channels welded and bolted. - Internal working portion painted with heat resisting Aluminium paint. - Chamber base made of heavy plates - Double walled oven is insulated with required thermal insulation on all sides to avoid heat loss - Specially designed heating elements provided on top and bottom of the chamber - Special fitting of heating elements and independent thermostatic control of bottom and top heating. Separate ON/OFF switches provided for both top and bottom heating systems. - Elements made from high grade Nichrome resistance wire - Elements easily replaceable - All units completely assembled and delivered ready to use. No foundation required - Temperature controlled with a German thermostat (EGO make) through air break contactors - Temperature range: 50 to 300 degrees centigrade (celsius) - The oven reaches baking temperature in 1.0 to 1.5 hours and can be quickly adjusted to lower or higher temperatures - Light bulbs fitted in the oven for observing the baking process |

SPECIFICATIONS:

Optional: Proover, Automatic Steaming system, stand with legs, stand with castor wheels |

|

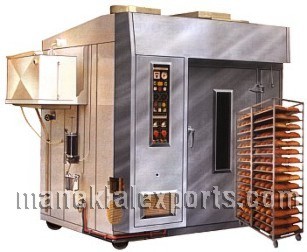

| Multipurpose Diesel Rotary Rack Oven |

|

- The required (cold to 250

degrees centigrade) temperature is attained in 25 to 30 minutes - When the oven reaches its baking temperature, simply open the door and push the rack into the baking chamber. The rack will automatically stop at its correct position - A signal informs you that the baking cycle is over - Heat Exchanger: An oil or or Gas burner produces the energy in a heat exchanger. A fan circulates the air around in the heat exchanger and into the baking chamber. This hot air bakes the products. The hot air is re-circulated to the heat exchanger. - The front of the oven is made of Stainless Steel 304 - Simple to read and easy to use Control Panel provided in conformity with the safety standards - 24 hours continuous working capacity -Smokeless and soundless. It can also be installed in residential areas or/and at higher floors - Full view glass door - Automatic greasing system - Fitted with self cleaning system. Indicator to show whether the tank is empty or full - Suitable for bakeries, hotels as well as fast food joints - Can be provided to operate on three phase or single phase supply voltage |

SPECIFICATIONS:

|

|

||||||||||||||||||||||||

| Bread Slicer |

|

- Designed to slice different

types of Breads, Rusks, Cakes, etc. - Output of around 600 loaves of 400 gms per hour - Suitable frames can be provided to suit your preferred slice thickness -The loaves of bread / rusks are to be placed one behind the other on the gravity feeding tray. They are sliced without wastage. The vertical running knives slice the loves at equal thickness as per requirement. - All steel welded construction - Grease packed heavy duty ball and roller bearings for smooth operation - Knives individually mounted under balanced tension - Frames giving different slice thickness can be fitted - All contact parts are chrome plated |

SPECIFICATIONS:

|

|

| High Speed Bread Slicer |

|

- Designed to slice cakes,

breads, rusks, etc. including delicate products or soft and sticky

products - All contact parts are chrome plated - PVC coated endless conveyor belt for hygienic operation - The crank drive rotates in a strong and totally enclosed casing containing lubricating oil - Knives holders of high quality cast aluminium - Additional knife holders can be provided with different slice thickness. Easy replacement of frames holding the knives. - All rotating parts on ball bearings to reduce wear and tear |

| SPECIFICATIONS: Capacity: 1800 to 2000 loaves of 400 to 800 gms per hour Motor: TWO 3 HP and ONE 1 HP motors Slice Thickness: 9 mm. (Other thickness available at extra cost) No. of knives fitted: 36 x 14.625" Weight: 1250 kgs. Dimensions: 4.0 x 1.3 x 0.8 m |

|

| Cake Mixer (Planetary Mixer) |

|

- Planetary action with three

speeds - 38, 128 and 170 RPM for perfect mixing. The agitator rotates on

its axis in the opposite direction to the bowl. This lets the agitator

reach every part of the batch for the most uniform mixing, thoroughly

blending and aerating all the ingredients - Mixers supplied with a Stainless Steel bowl, Flat Beater and Wire Whip. A Dough Hook and a Bowl Truck can be supplied optionally at extra cost - All contact parts are made from Stainless Steel 304 - Gears are heat treated alloy steel and in mesh in a special lubricant assuring quiet operation and long life SPECIFICATIONS:

|

|

| Bun Divider (Semi Automatic Bun Divider, Rounder, Moulder Machine) |

|

- The machine divides,

Rounds and Moulds the dough into 30 divisions Scaling Range 40 to 70 gms.

SPECIFICATIONS: |

| Bun Slicer |

|

- An easy to operate and

inexpensive machine with simple adjustment for varying position and depth

of slice - Fitted with high tensile steel blade for years of trouble free operation - 'Soft Touch' door provides smooth and gentle discharge of sliced products

SPECIFICATIONS: |

|

ASK FOR

OUR PRICE LISTS ON THE FOLLOWING: |

|

Maneklal

Global Exports |

|

TO OUR PAGE ON FOOD PROCESSING EQUIPMENT |