|

|

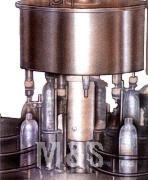

| Rinser - Filler - Capper: Monoblock three-in-one machine |

|

-

Incorporates Rotary Rinsing - Rotary Gravi Filling and Rotary

Screw-on Capping operations on a single base - Rinsing device uses neck grippers to invert the bottles for Rinsing and automatically unloads into the inlet turret of the Gravi Filling section in the upright position after Rinsing internally - Bottles once located in the Rinsing Station are released only after all the three operations (Rinsing - Filling - Capping) are over - Adequate neck holders provided at the Filling and Capping Stations to eliminate buckling of Pet Bottles - Universal Hopper provided for automatic Capping provided diameter of the caps is larger then its height - No bottle - No Rinse. No bottle - No Fill, No bottle - No Cap. - Available in two models: RFC-L (with 16 jets Rinsing + 16 heads Filling + 8 heads Capping combinations) and RFC-S (with 8 jets Rinsing + 6 heads Filling + 6 heads Capping combinations) - Can be adapted to Rinse, Fill and Cap bottles from 200 ml upto 2000 ml in a single stroke. - Approximate output speeds of 24 bpm and 60 bpm for 1 litre Mineral Water Bottles on the above two models possible. Can also accommodate other sizes of bottles with the help of change parts on request |

| - Can also be adapted for other

applications like juices, squashes, etc. in Pet / Glass bottles. Outputs

will depend on volume of fill and type / characteristics of liquid to be

filled - Water for Rinsing (either by Gravity or Pump) to suit jetting force required and Liquid Product for filling along with a buffer feed tank and pump to stop / start. Liquid Level Controller is to be provided by you. - 2/3 HP electric motor for main drive (depending on the model), 0.5 HP electric motor for Screw-on Capping head drive and 0.25 HP motor for Hopper drive - Approximate size of Machine: 3.7 x 2.5 x 1.6 m - Approximate Weight: 2000 to 3000 kgs. (depending on model) |

Rinsing |

Filling |

Capping |

|

|

|

Maneklal

Global Exports |

|

TO OUR PAGE ON FOOD PROCESSING EQUIPMENT |