|

|

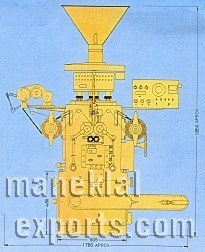

| Maquinas Rotativas para Pastillas: |

|

|

|

- Para producción de pastillas en varios

tamaños y formas - Útil en las industrias de farmacéuticos, cosméticos, productos de comida, plásticos, metalurgia, químicas y pesticidas - Modelos de serie 'JM' y 'JS' son Single Sided disponible en tipo estándar y GMP* - Modelos de serie 'JD' son Double Sided disponible en tipo estándar y GMP* - Modelos de serie 'DH' son Double Sided disponible solo en tipo GMP* - Pre Compression Option and Bi Layer Tablet Option available on the 'JD' and 'DH' series models |

|

|

|

|

|

| Modelo: | JM-6 | JM-8 | JM-10 | JM-12 | JM-16 | JS-16 | JS-20 | JS-23 |

| Tipo: | Single Sided - tipo estándar & GMP | Single Sided - tipo estándar & GMP | ||||||

| No.

de Estaciones: |

6 | 8 | 10 | 12 | 16 | 16 | 20 | 23 |

|

Tipo

de Herramientas: |

D | D | D | D | B | D | D | B |

|

Presión

de compresión Máx. (Toneladas): |

6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 10 | 10 | 6.5 |

|

Tamano max. de la pastilla (mm): |

25 | 25 | 25 | 25 | 16 | 25 | 25 | 15 |

|

Profundidad max. de la pastilla (mm): |

20 | 20 | 20 | 20 | 16 | 20 | 20 | 16 |

|

Motor: |

1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 |

| Torrecilla

RPM (Min. / Máx.) |

18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 |

| Producción

(Pastillas

por Minuto) Min. / Máx.: |

108 / 200 | 145 / 265 | 180 / 330 | 220 / 400 | 300 / 530 | 290 / 450 | 360 / 560 | 460 / 760 |

| Peso Neto / Bruto (kgs.) tipo GMP: | 950 / 1450 | 1200 / 1800 | ||||||

| Dimensiones (m) tipo GMP: | 0.94 x 0.94 x 1.96 | 1.30 x 1.30 x 2.34 | ||||||

| Peso Neto / Bruto (kgs.) tipo estándar: | 650 / 1150 | 850 / 1450 | ||||||

| Dimensiones (m) tipo estándar: | 0.94 x 0.94 x 1.70 | 1.10 x 1.05 x 1.95 | ||||||

|

|

|

|

| Model: | JD-23 | JD-27 | JD-35 | JD-45 | DH-45 | DH-55 | DH-65 | DH-71 |

| Tipo: | Double Sided - tipo estándar y GMP | Double Sided - tipo GMP | ||||||

| No.

de Estaciones: |

23 | 27 | 35 | 45 | 45 | 55 | 65 | 71 |

|

Tipo

de Herramientas: |

D | D OR B | B | BB | D | B | BB | BB |

|

Presión

de compresión Máx. (Toneladas): |

10 | 6.5 | 6.5 | 6.5 | 10 | 6.5 | 6.5 | 6.5 |

|

Tamano max. de la pastilla (mm): |

25 | 25 / 16 | 16 | 13 | 25 | 16 | 13 | 11 |

|

Profundidad max. de la pastilla (mm): |

20 | 20 / 16 | 16 | 16 | 20 | 16 | 16 | 16 |

|

Motor: |

3 | 3 | 3 | 3 | 5 | 5 | 5 | 5 |

| Torrecilla

RPM (Min. / Máx.) |

18 / 33 | 18 / 33 | 18 / 33 | 18 / 33 | 20 / 50 | 20 / 50 | 20 / 50 | 20 / 50 |

| Producción

(Pastillas

por Minuto) Min. / Máx.: |

850 / 1520 | 980 / 1780 | 1260 / 2310 | 1620 / 2970 | 1800 / 4500 | 2200 / 5500 | 2600 / 6500 | 2850 / 7100 |

| Peso Neto / Bruto (kgs.) tipo GMP: | 1500 / 2200 | 3200 / 4000 | ||||||

| Dimensiones (m) tipo GMP: | 1.35 x 1.35 x 2.35 | 1.60 x 1.60 x 2.35 | ||||||

| Peso Neto / Bruto (kgs.) tipo estándar: | 1100 / 1800 | N.A. | ||||||

| Dimensiones (m) tipo estándar: | 1.20 x 1.20 x 1.95 | N.A. | ||||||

|

#Nota: Con modelos de

serie 'JD' tipo GMP la velocidad seria entre 20 y 40 RPM |

|

|

|

|

|

Accesorios

Estándar:

Motor

Eléctrico, juegos de punzones y matrices (redondas) Accesorios Opcionales: Equipo para Extracción de Polvo, Tablet De-Duster complete with SS body, punzones y matrices (redondas) adicionales, punzones y matrices (cápsula) |

|

|

|

| We undertake Turnkey Projects for Making Tablets, Powder, Liquid, Ointment, Injectable, Hard & Soft Gelatin Capsules, etc |

| - Suitable for

high speed sealing of coated or uncoated tablets, capsules, lozenges,

etc. of any shape or size in aluminium foils, polythene, cellophane or

any other heat sealing material - Feeding: Fully automatic vibrator with hopper - Chutes: 2, 4, 6, 8 or 10 tracks to suite your application - Sealing Rollers: High precision carbon steel rollers, machined knurled, heat treated for minimum wear and tear, fitted with high quality heating elements - Cutting Mechanism: Horizontal and vertical cutting as required, achieved by steel knives fitted under the rollers and between the draw bushes - Controls for Operation: A Start - Stop switch is provided for the machine. A clutch for starting / Stopping the sealing rollers and a release mechanism for starting / stopping the feeding of tablets also provided. Rolls of the packing material are mounted on two shafts and knobs are fitted at the ends of the shafts for adjusting and positoningthe rolls of the packing material in relation to the sealing rollers. - Speed Control: By variable speed drive |

|

|

|

| Model: | SSM-2 | SSM-4 | SSM-6 | SSM-8 | SSM-10 |

| Min. Output (Tablets/Minute): | 600 | 1200 | 1800 | 2400 | 3000 |

| Max. Output (Tablets/Minute): | 850 | 1700 | 2400 | 3000 | 3500 |

| Foil Width (mm): | 70 | 140 | 210 | 250 | 300 |

| Motor (HP): | 1 | 1 | 1 | 1 | 1 |

| Heater: | 2 x 500W | 2 x 500W | 2 x 1000W | 2 x 1200W | 2 x 1500W |

|

|

|

Productos

Envasado:

Pastillas, Cápsulas,

Cápsulas de

Gelatina, etc. Materia

de Envase: PVC base film web is drawn off from a reel and fed into the blister-forming unit where blisters are continuously formed. The web is then passed over the guide track where the product is filled into the blisters by a suitable automatic filling unit and led to the sealing unit. Aluminium foil is drawn off a separate reel and is fed to the sealing unit where it is sealed with the base web, thus sealing the product hermetically. The filled and sealed web is then fed by an indexing mechanism into a pack punch unit where the packs are separated from the web. The web trim is sheared off to allow collection. The blister pack may either be collected in bins or be conveyed over a belt for further handling. The machine could also be linked to a cartoner. |

|

Modelo: 100 CH-CW |

Model: 150 CH-CW / 240 CH-CW |

| Model: | 100 ch-cw | 150 ch-cw | 240 ch-cw |

| PVC Base Film Width max. (mm): | 120 | 120 | 210 |

| PVC Film Thickness max. (mm): | 0.2 - 0.3 | 0.2 - 0.3 | 0.2 - 0.3 |

| PVC Reel Diameter max. (mm): | 440 | 440 | 440 |

| Aluminium Foil Width max. (mm): | 116 | 116 | 206 |

| Aluminium Foil Thickness max. (mm): | 0.02 - 0.03 | 0.02 - 0.03 | 0.02 - 0.03 |

| Aluminium Foil Roll Diameter max. (mm): | 210 | 210 | 210 |

| Total Forming Area min. (mm): | 120 x 25 | 120 x 25 | 210 x 25 |

| Total Forming Area max. (mm): | 120 x 102 | 120 x 102 | 210 x 102 |

| Pack Length (mm): | 110 | 110 | 200 |

| Pack Width (mm): | 100 | 100 | 100 |

| Forming Depth (mm): | 10 | 10 | 10 |

| Output (Packs) / (tabs/min.): | 100 / 1000 | 150 / 1500 | 240 / 2400 |

| Power Requirement (kW): | 2.5 | 4.5 | 9.0 |

| Net / Gross Weight (Kgs.): | 600 / 900 | 1050 / 1500 | 2000 / 2600 |

| Overall Dimensions (m): | 1.6 x 1.0 x 1.6 | 2.3 x 1.0 x 1.9 | 3.6 x 1.0 x 1.9 |

| Shipping Volume (m3): | 2.6 | 4.4 | 6.9 |

|

Standard Accessories:

Blister Forming Roller, Feeding

Channel, Guide Track, Punch Tool, Support Sealing Roller (only on models 150

ch-cw and 240 ch-cw)

Optional Accessories:

Extra

set of standard Change Parts (including Blister Forming Roller, Feeding Channel,

Guide Track, Punch Tool, Support Sealing Roller (only on models 150 ch-cw and

240 ch-cw)), Punch Tool with Embossing, Batch Code Printing Unit, Scoring Unit,

Tablet Recovery Machine (De-Blister), Print Mark Registration Control (only on

models 150 ch-cw and 240 ch-cw) |

|

We can also supply: Strip Packing Machines, Capsule Filling Machines, Liquid Filling Machines, Bottling Machines, High Speed Mixers, Planetary Mixers, Sifters (for Sieving and Grading), Multi Mills (for Granulating, Pulverizing, Shredding, Chopping, etc.), Coating Pans, Dies and Punches for Tablets, Drying Ovens, etc. |

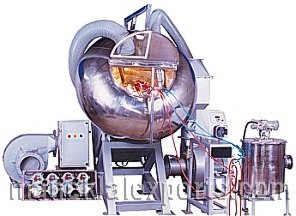

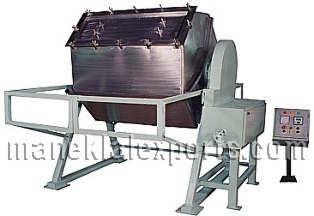

| Fluid Bed Dryer, Planetary Mixer for Ointment Mixing, High Speed Mixer Granulators, Auto Coaters, Coating Pans, Octagonal Blenders, etc.: |

Fluid Bed Dryer |

Planetary Mixer for Ointment Mixing |

Planetary Mixer |

Coating Pan |

Coating Pan |

Auto Coaters |

High Speed Mixer Granulators |

Octagonal Blenders |

| We undertake Turnkey Projects for Making Tablets, Powder, Liquid, Ointment, Injectable, Hard & Soft Gelatin Capsules, etc |

|

Tablet

Section: - Tablet Compression Machine: Rotary Tablet Presses, Punches and Dies, Tablet De-Duster, Dust Collector - Wet Mixing and Granulation: High Speed Mixer Granulator, Planetary Mixer, Mass Mixer, Starch Paste Kettle, Sigma Mixer - Milling: Multimill, Oscillating Granulator, Ball Mill - Drying: Fluid Bed Dryer, Rotocone Dryer, Tray Dryer - Dry Blending: Octagon Blender, Double Cone Blender, Ribbon Blender, Drum / IPC Blender / V/Y Blender - Sieving: Vibro Sifter / Turbo Sifter - Sugar / Film Coating: Auto Coater, Coating Pan and System - Material Handling / Transfer Devices: In process containers, IPC lifting and loading devices, Bowl lifting and tilting device, Screw conveyors Capsule: |

Liquid

Section: - Sugar Sieving: Vibro Sifter, Turbo Sifter - Sugar Loading: In process containers, IPC lifting & loading device, Screw Conveyor - Sugar Syrup Preparation Tank: Vertical Jacketed, Agitated Tanks - Mixing Tank: Vertical Jacketed, Agitated Tanks - Storage Tank: Vertical / Horizontal Plain Tanks - Lobe / Transfer Pumps - Filter Press - Colloid Mill - Agitators - Homogenisor - Filling Machine - Bottle Washing Machine - Capping & Sealing Machine - Labelling Machine - Inspection Table - Packing Conveyors - Transfer Pipe Line & Filters Ointment Section: |

|

Maneklal Global Exports |