|

|

|

Machines for Making EAST-WEST (Bent Ends) Type Bucket Handles |

|

|

Model: BHM-25EP - For Handle Type East-West (Bent Ends) with Plastic Grip |

|

|

|

Model: BHM-10EP - For Handle Type East-West (Bent Ends) with Plastic Grip |

|

VIDEO of EAST-WEST (BENT ENDS) Type Bucket Handle Making Machines |

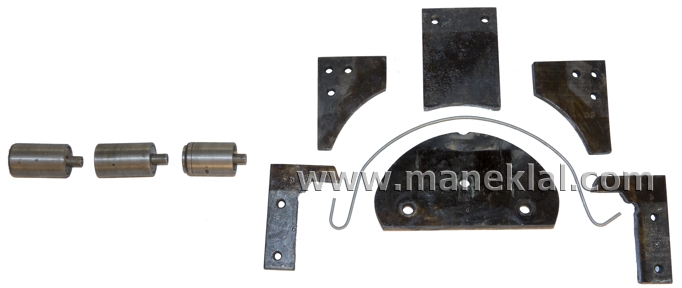

Additional Die for East-West (Bent Ends) Type Bucket Handle |

Die of Model: BHM-25EP |

System to insert Plastic Grips on Model: BHM-25EP |

|

Standard Accessories: Electric Motor,

Control Panel, Coil Stand, One Set of Toolings (for any one

size of handle) |

|

|

Model: BHM-25HK - For Handle Type OK (Hook Ends) with Plastic Grip |

|

|

|

|

|

VIDEO of OK (HOOK ENDS) Type Bucket Handle Making Machines |

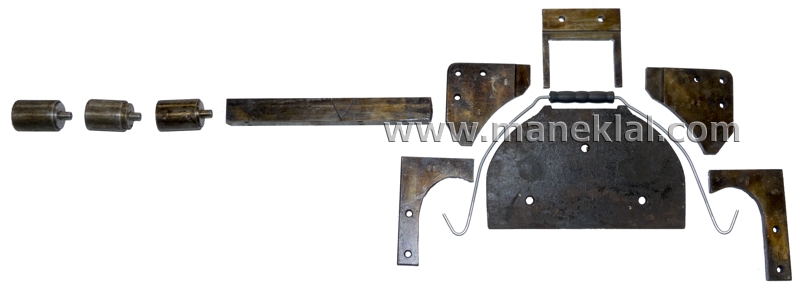

Additional Die for OK (Hook Ends) Type Bucket Handle |

Additional Die for OK (Hook Ends) Type Bucket Handle |

Additional Die for OK (Hook Ends) Type Bucket Handle |

|

Standard Accessories: Electric Motor,

Control Panel, Coil Stand, One Set of Toolings (for any one

size of handle) |

|

Machines for Making REGULAR (Notches at Ends) Type Bucket Handles |

|

|

|

|

|

|

Model: BHM-10R - For Handle Type Regular (Notches at Ends) |

|

VIDEO of REGULAR (NOTCHES AT ENDS) Type Bucket Handle Making Machines |

|

Standard Accessories: Electric Motor,

Control Panel, Coil Stand, One Set of Toolings (for any one

size of handle) |

|

|

Horizontal Hydraulic, Fully Automatic Plastic Injection Moulding Machine, Screw Type |

Model: IN-75S |

|

|

Specifications: |

| Model: | IN - 75S | IN - 100S |

| Screw Diameter (mm): | 30 | 35 |

| Max. Moulding Capacity* (gm.): | 75 | 100 |

| Max. Injection Pressure (kg/cm2): | 1200 | 1800 |

| Max. Plasticising Capacity* (kg/hr): | 18 | 18 |

| Max. Shots per Hour* (no/hr): | 240 | 180 |

| Dry Cycles per Hour: | 400 | 350 |

| Max. Swept Volume (cm3): | 90 | 120 |

| Max. dimensions of mould L x B x H (mm): | 270 x 250 x 270 | 290 x 300 x 300 |

| Max. Mould Opening (mm): | 250 | 300 |

| Number of Tie Bars (nos.): | 2 | 4 |

| Clear Gap between Tie Bars (mm): | 300 | 320 x 145 |

| Centre Height of Injection Nozzle (mm): | 190 | 225 |

| Clamping Force (tons): | 35 | 60 |

| Max. Pump Pressure (adjustable) (kg/cm2): | 140 | 140 |

| Oil Tank Capacity (liters): | 115 | 175 |

| Electric Motor (HP): | 10 | 12.5 |

| Total Heating Load (kW): | 1.75 | 2.5 |

| Approximate Machine Dimensions (mm): | 2500 x 600 x 1400 | 2800 x 750 x 1600 |

| Approximate Net / Gross Weight (Kg.): | 1500 / 1700 | 2700 / 3000 |

| Approximate Shipping Volume (m3): | 3.10 | 4.70 |

Model: IN-100S |

|

Thermoplastics Moulded: Polystyrenes, Polyethylenes, Polypropylenes, acrylics, ABS, flexible PVC, rigid PVC (in Screw Type machines only), etc. Extra optional Nozzles available for moulding Nylon, Polyester, etc. * - Depends on material, processing conditions, individual articles, mould design, etc. |

|

VIDEO OF IN-75S INJECTION MOULDING MACHINE |

|

VIDEO OF IN-100 INJECTION MOULDING MACHINE |

|

VIDEO OF 10 CAVITY INJECTION MOULDING DIE FOR MAKING PLASTIC GRIPS |

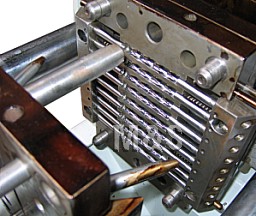

9 Cavity Die for making Plastic Grips with IN-75S |

10 Cavity Die for making Plastic Grips |

16 Cavity Die for making Plastic Grips with IN-100S |

|

Plastic Injection Moulding Machine with 2 Station - 16 Cavity Die for moulding Fixed Plastic Grips on Bucket / Paint Can Handles |

Model: MIM-80 |

Features: - Hydraulics of Sufon / Hyten - Two side Hydraulic Ejector - 4 Zone Ceramic Heater - Oil Cooler provided - Carriage Unit UP / DOWN hydraulic system - PLC of Streamline - Linear Scale of Opkon / Orbital |

PLC Control Panel |

|

Specifications:

|

Standard Accessories: Electric Motor, Control Panel. PLC Unit, Hydraulic Power Pack, Tool Kit Optional Accessories: Die for moulding plastic grips on bucket handles |

||||||||||||||||||||||||||

|

VIDEO OF MIM-80 INJECTION MOULDING MACHINE |

16 Cavity Die for moulding Plastic Grips |

16 Cavity Die for moulding Plastic Grips |

16 Cavity Die for moulding Plastic Grips |

|

Vertical Hydraulic, Semi-Automatic Plastic Injection Moulding Machine, Plunger Type |

Model: 40HM |

Die for fixing Plastic Grips |

|

Specifications: |

| Model: | 40HM |

| Max. Moulding Capacity (gm.): | 40 |

| Stroke of Injection Plunger (mm): | 150 |

| Injection Pressure - adjustable (kg/cm2): | 1200 |

| Clamping Force - adjustable (tons): | up to 4 |

| Clamping Stroke (mm): | 125 |

| Working Base Width (mm): | 175 |

| Distance - back to barrel nozzle (mm): | 80 |

| Distance - barrel nozzle to base - adjustable (mm): | 80 - 175 |

| Max. Moulding Area (mm2) | 5000 |

| Electric Motor (HP): | 2 |

| Electric Heater (kW): | 0.75 |

| Approximate Machine Dimensions (mm): | 1500 x 610 x 1500 |

| Approximate Net / Gross Weight (Kg.): | 175 / 250 |

| Approximate Shipping Volume (m3): | 1.40 |

|

VIDEO OF 40-HM INJECTION MOULDING MACHINE |

|

Maneklal Global Exports |

|

TO OUR PAGE ON SMALL SCALE INDUSTRY PROJECTS |