|

|

|

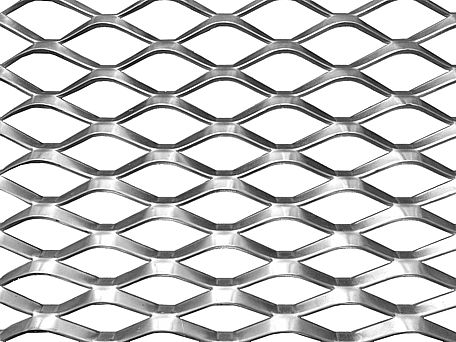

- Steel, Aluminium, Brass and other non-ferrous metal sheets

formed into mesh by cutting and stretching

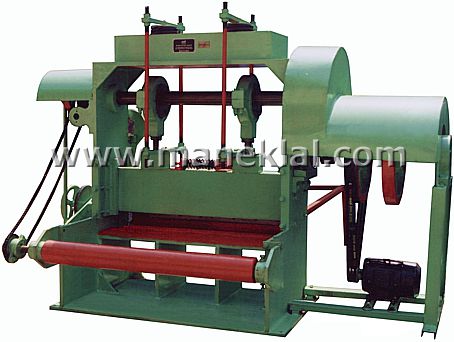

Operation: The sheet is fed to the blades by means of rollers. A toothed upper blade cuts the sheet in conjunction with the straight stationary lower blade at right angle to the feed direction in such a way that a web of certain width remains standing which is stretched when the upper blade goes down. With the next stroke of the slide the cycle is repeated. The operation of Cutting - Stretching - Feeding is automatic. |

|

|

|

Specifications: |

*Note: EMM - 2.5 is shipped in a open top container in unpacked condition. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Standard Accessories: Suitable Electric Motor, Starter, ‘V’

Belts, One die set suitable for any one mesh size and sheet thickness

Optional Accessories: Decoiler, Coiler, Flattening Machine, Straightening Machine, Brushing Unit, Die sets for different sizes of mesh |

|

VIDEO ON HIGH-SPEED MACHINE FOR MAKING EXPANDED METAL MODEL: EMM-1.2/HS |

|

Maneklal Global Exports |

|

TO OUR PAGE ON SMALL SCALE INDUSTRY PROJECTS |