|

|

|

|

In Line: Wire Feeder - Extruder Press - Conveyor - Electrode Name Printing Unit |

|

|

Extruder Press |

Wire Feeder |

Briqueting /Slug Press |

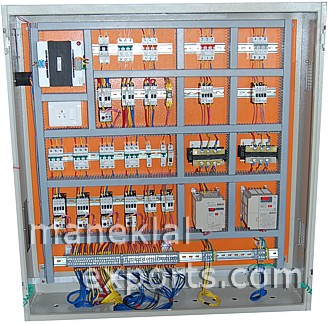

Control Panel |

Control Panel |

| Specifications: |

| Capacity per Shift (8 hours): | ONE TON | TWO TONS | THREE TONS | FIVE TONS | SIX TONS | EIGHT TONS | TEN TONS |

| Dry Mixer Model: | DM-200 | DM-300 | DM-300 | DM-500 | DM-500 | DM-1000 | DM-1000 |

| Pan Diameter x Length: | 500 x 900 mm | 600 x 1000 mm | 650 x 1000 mm | 650 x 1500 mm | 650 x 1500 mm | 850 x 2100 mm | 850 x 2100 mm |

| Top Door Opening: | 550 x 900 mm | 300 x 1000 mm | 300 x 1000 mm | 600 x 1500 mm | 600 x 1500 mm | 400 x 2000 mm | 400 x 2000 mm |

| Discharge Door: | 225 x 225 mm | 225 x 225 mm | 225 x 225 mm | 225 x 225 mm | 225 x 225 mm | 225 x 225 mm | 225 x 225 mm |

| Motor: | 2 HP | 3 HP | 3 HP | 7.5 HP | 10 HP | 15 HP | 15 HP |

| Gear Box: | 287 | 337 | U3 | U5 | U5 | U6 | U6 |

| Wet Mixer Model: | WM-35 | WM-50 | WM-75 | WM-125 | WM-125 | WM-250 | WM-250 |

| Shell Diameter x Height: | 1000 x 450 mm | 1100 x 450 mm | 1200 x 450 mm | 1250 x 500 mm | 1250 x 500 mm | 1500 x 650 mm | 1500 x 650 mm |

| Wheel Diameter: | 350 x 90 mm | 350 x 110 mm | 350 x 110 mm | 410 x 110 mm | 410 x 110 mm | 500 x 160 mm | 500 x 160 mm |

| Motor: | 3 HP | 5 HP | 7.5 HP | 15 HP | 15 HP | 20 HP | 20 HP |

| Gear Box: | 337 | V4 | V4 | V6 | V6 | V9 | V9 |

| Slug Press Model: | SP-6 | SP-6 | SP-6 | SP-12 | SP-12 | SP-40 | SP-40 |

| Normal Press Capacity: | 6 Tons | 6 Tons | 6 Tons | 12 Tons | 12 Tons | 40 Tons | 40 Tons |

| Operating Pressure: | 120 kg/cm2 | 120 kg/cm2 | 150 kg/cm2 | 150 kg/cm2 | 150 kg/cm2 | 180 kg/cm2 | 180 kg/cm2 |

| Oil Cylinder Bore: | 80 mm | 80 mm | 80 mm | 125 mm | 125 mm | 150 mm | 150 mm |

| Piston Rod Diameter: | 45 mm | 45 mm | 45 mm | 70 mm | 70 mm | 90 mm | 90 mm |

| Flux Cylinder Bore: | 95 mm | 100 mm | 100 mm | 145 mm | 145 mm | 200 mm | 220 mm |

| Unit Pressure on Flux (max): | 450 kg/cm2 | 450 kg/cm2 | 450 kg/cm2 | 550 kg/cm2 | 550 kg/cm2 | 800 kg/cm2 | 800 kg/cm2 |

| Slug Height: | 120 mm | 120 mm | 150 mm | 150 mm | 150 mm | 200 mm | 200 mm |

| Pump Motor: | 2 HP | 2 HP | 3 HP | 5 HP | 5 HP | 7.5 HP | 10 HP |

| Pump Capacity: | 8 Ltr / min | 8 Ltr / min | 8 Ltr / min | 15 Ltr / min | 15 Ltr / min | 30 Ltr / min | 30 Ltr / min |

| Wire Feeder Model: | WF-1 | WF-2 | WF-3 | WF-5 | WF-6 | WF-8 | WF-10 |

| Range of Wire Diameter: | 2.5 to 4.0 mm | 2.5 to 6.3 mm | 2.5 to 6.3 mm | 2.5 to 6.3 mm | 2.5 to 6.3 mm | 2.5 to 6.3 mm | 2.5 to 6.3 mm |

| Length of Wire: | 250 – 450 mm | 250 – 450 mm | 250 – 450 mm | 250 – 450 mm | 250 – 450 mm | 250 – 450 mm | 250 – 450 mm |

| Max. Wire Feeding Speed: | 250 pcs / min | 400 pcs / min | 450 pcs / min | 800 pcs / min | 800 pcs / min | 1100 pcs / min | 1100 pcs / min |

| Hopper Capacity: | 200 kilos | 250 kilos | 250 kilos | 250 kilos | 250 kilos | 350 kilos | 350 kilos |

| Motor: | 2 HP | 3 HP | 3 HP | 5 HP | 5 HP | 5 HP + 5 HP | 7.5 HP + 5 HP |

| Adj. Motor: | -- | -- | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP |

| Extruder Model: | EP-50-1T | EP-50-2T | EP-75 | EP-125 | EP-150 | EP-200 | EP-250 |

| Total Press Capacity: | 50 Tons | 50 Tons | 75 Tons | 125 Tons | 150 Tons | 200 Tons | 250 Tons |

| Hydraulic Operating Pressure: | 160 kg/cm2 | 160 kg/cm2 | 160 kg/cm2 | 180 kg/cm2 | 180 kg/cm2 | 200 kg/cm2 | 200 kg/cm2 |

| Unit Pressure on Flux: | 580 kg/cm2 | 580 kg/cm2 | 950 kg/cm2 | 950 kg/cm2 | 950 kg/cm2 | 1000 kg/cm2 | 1250 kg/cm2 |

| Hydraulic Cylinder Bore: | 200 mm | 210 mm | 250 mm | 330 mm | 330 mm | 450 mm | 500 mm |

| Total Ram Stroke: | 800 mm | 900 mm | 900 mm | 1100 mm | 1100 mm | 1100 mm | 1100 mm |

| Extrusion Cylinder Bore: | 100 mm | 105 mm | 105 mm | 150 mm | 150 mm | 205 mm | 225 mm |

| Pump Capacity: | 15 Ltr / min | 12/36 Ltr / min | 12/46 Ltr / min | 25/210 Ltr / min | 30/210 Ltr / min | 40/260 Ltr / min | 40/260 Ltr / min |

| Pump Motor: | 5 HP | 7.5 HP | 10 HP | 15 + 20 HP | 15 + 20 HP | 20 + 30 HP | 20 + 30 HP |

| Conveyor Model: | 1-T | 2-T | 3-T | 5-T | 6-T | 8-T | 10-T |

| Range of Wire Diameter: | 2.5 to 5.0 mm | 2.5 to 5.0 mm | 2.5 to 5.0 mm | 2.5 to 6.3 mm | 2.5 to 6.3 mm | 2.5 to 6.3 mm | 2.5 to 6.3 mm |

| Length: | 350 to 450 mm | 350 to 450 mm | 350 to 450 mm | 350 to 450 mm | 350 to 450 mm | 350 to 450 mm | 350 to 450 mm |

| Drive Conveyor: | 1.5 HP | 2.0 HP (A/c Drive) | 2.0 HP (A/c Drive) | 2 HP (A/c Drive) | 2.0 HP (A/c Drive) | 2.0 HP (A/c Drive) | 3.0 HP (A/c Drive) |

| Central Conveyor: | -- | -- | -- | 1.5 HP (A/c Drive) | 1.5 HP (A/c Drive) | 1.5 HP (A/c Drive) | 2.0 HP (A/c Drive) |

| Unloading Conveyor: | -- | 0.5 HP | 1.0 HP (A/c Drive) | 1.0 HP (A/c Drive) | 1.0 HP (A/c Drive) | 1.0 HP (A/c Drive) | 1.0 HP (A/c Drive) |

| Transverse Conveyor: | 0.5 HP | 0.5 HP (A/c Drive) | 0.75 HP (A/c Drive) | 0.75 HP (A/c Drive) | 1.0 HP (A/c Drive) | 1.0 HP (A/c Drive) | 2.0 HP (A/c Drive) |

| Caterpillar: | 0.5 HP | 0.5 HP | 0.50 HP (A/c Drive) | 0.50 HP (A/c Drive) | 0.5 HP (A/c Drive) | 0.5 HP (A/c Drive) | 1.0 HP (A/c Drive) |

| Printing Unit: | 0.25 HP (A/c Drive) | 0.25 HP (A/c Drive) | 0.25 HP (A/c Drive) | 0.25 HP (A/c Drive) | 0.25 HP (A/c Drive) | 0.25 HP (A/c Drive) | 0.5 HP (A/c Drive) |

| Brushing: | 0.5 HP | 0.5 HP x 2 | 0.75 HP x 2 | 0.75 HP x 2 | 0.75 HP x 2 | 0.75 HP x 2 | 1.0 HP x 2 |

| Tip End Cleaning: | 0.5 HP | 0.5 HP | 0.75 HP | 0.75 HP | 0.75 HP | 0.75 HP | 1.0 HP |

| Wire Straightening & Cutting Machine Model: | LT-100 | LT-200 | LT-200 | LT-200 | LT-200 | LT-200 | LT-200 |

| Wire Diameter: | 2.0 to 4.0 mm | 2.0 to 5.0 mm | 2.0 to 5.0 mm | 2.0 to 5.0 mm | 2.0 to 5.0 mm | 2.0 to 5.0 mm | 2.0 to 5.0 mm |

| Cuts / Length: | 250 to 450 mm | 250 to 450 mm | 250 to 450 mm | 250 to 450 mm | 250 to 450 mm | 250 to 450 mm | 250 to 450 mm |

| Cuts / Minute: | 100 to 150 nos. | 160 to 210 nos. | 160 to 210 nos. | 160 to 210 nos. | 160 to 210 nos. | 160 to 210 nos. | 160 to 210 nos. |

| No. of Straightening Dies: | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Motors: | 5 HP | 5 + 2 + 1 HP | 5 + 2 + 1 HP | 5 + 2 + 1 HP | 5 + 2 + 1 HP | 5 + 2 + 1 HP | 5 + 2 + 1 HP |

| Baking Oven Model: | BO-1/24 | BO-2/32 | BO-3/32 | BO-5/48 | BO-6/48 | BO-8/86 | BO-10/86 |

| Chamber Size (W x D x H): | 1.0 x 1.0 x 1.0 m | 1.5 x 1.5 x 1.65 m | 1.5 x 1.5 x 1.65 m | 2.2 x 1.5 x 1.5 m | 2.5 x 1.5 x 1.5 m | 5.0 x 1.5 x 1.5 m | 5.0 x 1.5 x 1.5 m |

| Max. Temperature: | 250o C | 250o C | 250o C | 250o C | 250o C | 250o C | 250o C |

| Heater Coils: | 24 HP (18 kW) | 32 HP (24 kW) | 32 HP (24 kW) | 48 HP (36 kW) | 48 HP (36 kW) | 80 HP (60 kW) | 80 HP (60 kW) |

| Blower Motor: | 1 HP | 1.5 HP | 1.5 HP | 1.5 HP x 2 | 1.5 HP x 2 | 1.5 HP x 2 | 1.5 HP x 2 |

| Suitable for: | E-6013 electrodes | E-6013 electrodes | E-6013 electrodes | E-6013 electrodes | E-6013 electrodes | E-6013 electrodes | E-6013 electrodes |

| Note: | We offer higher capacity ovens of 500oC for special electrodes like: E-6010, E-6011, E-7018, Stainless Steel, etc. | We offer higher capacity ovens of 500oC for special electrodes like: E-6010, E-6011, E-7018, Stainless Steel, etc. | We offer higher capacity ovens of 500oC for special electrodes like: E-6010, E-6011, E-7018, Stainless Steel, etc. | We offer higher capacity ovens of 500oC for special electrodes like: E-6010, E-6011, E-7018, Stainless Steel, etc. | We offer higher capacity ovens of 500oC for special electrodes like: E-6010, E-6011, E-7018, Stainless Steel, etc. | We offer higher capacity ovens of 500oC for special electrodes like: E-6010, E-6011, E-7018, Stainless Steel, etc. | We offer higher capacity ovens of 500oC for special electrodes like: E-6010, E-6011, E-7018, Stainless Steel, etc. |

| Wet De-Coating Machine for Recovering Defective Electrodes with Wet Flux Model: | WDM-96 | WDM-96 | WDM-96 | WDM-96 | WDM-96 | WDM-96 | WDM-96 |

| Pan Length x Width: | 460 x 300 mm | 460 x 300 mm | 460 x 300 mm | 460 x 300 mm | 460 x 300 mm | 460 x 300 mm | 460 x 300 mm |

| Top Door Opening: | 700 x 500 mm | 700 x 500 mm | 700 x 500 mm | 700 x 500 mm | 700 x 500 mm | 700 x 500 mm | 700 x 500 mm |

| Discharge Door: | 275 x 275 x 300 mm | 275 x 275 x 300 mm | 275 x 275 x 300 mm | 275 x 275 x 300 mm | 275 x 275 x 300 mm | 275 x 275 x 300 mm | 275 x 275 x 300 mm |

| Number of Discs: | 96 | 96 | 96 | 96 | 96 | 96 | 96 |

| Motor: | 2 HP | 2 HP | 2 HP | 2 HP | 2 HP | 2 HP | 2 HP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dry Mixer |

|

|

Wet Mixer |

|

|

Electrode Baking Oven |

Concentricity Tester |

|

|

Shrink Packing Machine |

|

Maneklal Global Exports |

|

TO OUR PAGE ON SMALL SCALE INDUSTRY PROJECTS |