|

|

Heavy Duty Bull Block Wire Drawing Machine - High Speed |

|

General Features: |

Fine Wire Drawing Machines |

| Operation: - The wire rod to be drawn is pointed in the Wire Pointing Machine. This pointed wire is inserted through the die of the first Wire Drawing Machine and fastened to a locking device on the drum. The drum is then started. As the drum rotates, the wire fastened to the drum gets pulled and coiled around the drum. Since the wire getting pulled is passed through the die having a higher inlet diameter and a lower outlet diameter, the drawn wire diameter gets reduced. - The starting end of the drawn wire is released from the lock of the first drum, is passed through the overhead loop and pulley provided, is brought down and is inserted through the die of the second drum and drawn through this die for further reduction. Thus, the wire is drawn through all the wire drawing drums of the set in a continuous manner to get the required finished diameter of the wire. - When the drum of the last wire drawing machine gets fully loaded with the drawn wire, the machine will be stopped to unload the finished material and then restarted. (If one opts for the continuous coiling machine, the drawing process will not have to be stopped for this purpose) - When the bundle of input rod finishes, the machine should be stopped. The end of this bundle is welded to the end of a new bundle of rod using the butt welding machine. Then the process is to be continued. - Also, in case of an accidental snapping of wire in between drums, the snapped ends are welded with the help of the butt welding machine and the process is continued. |

|

|

| General Specifications: |

| Model: | WD-810N | WD-760N | WD-660N | WD-610N | WD-560N | WD-510N | WD-455N | WD-405N | WD-305N |

| No. of Blocks: | 1 to 8 | 1 to 8 | 1 to 8 | 1 to 8 | 1 to 8 | 1 to 8 | 1 to 8 | 1 to 8 | 1 to 9 |

| Diameter of Drum: | 810 mm (32") | 760 mm (30") | 660 (26") | 610 (24") | 560 (22") | 510 (20") | 455 (18") | 405 (16") | 305 (12") |

| Inlet Wire Size (mm): | 12 | 10 | 8 | 6.35 / 6 / 5.5 | 5.5 | 3 | 3 | 3 | 1.8 |

| Finished Wire size (mm): | 5.5 | 4 | 3 | 2 | 2 | 1.35 | 1.35 | 1.35 | 0.7 |

| Motor (HP): | 60 / 50 / 40 | 60 / 50 / 40 | 50 / 40 / 30 | 50 / 40 / 30 | 40 / 30 / 25 | 20 / 15 | 20 / 15 | 20 / 15 | 10 / 7.5 / 5 |

| Approximate Weight (kg.): | 1800 | 1700 | 1650 | 1600 | 1500 | 1000 | 900 | 750 | 550 |

|

Note: On request, we undertake supply of Wire Drawing Machines as per customer’s production requirement and specifications of inlet and finished wire desired |

Single Die Holder Bull Block 30" (750 mm) Wire Drawing Machine |

Triple Die Holder Bull Block Wire Drawing Machine |

Double Die Holder Bull Block 32" (810 mm) Wire Drawing Machine |

Double Decker Wire Drawing Machine with Killing Rollers for High Carbon Wire |

| Standard Equipment: Electric Motors, Pulleys, V Belts, Motor Rail, Continuous Drawing attachment, One Spool with Base, Pulling-in-Tong with lock, key and chain. |

| Auxiliary Equipment: Wire Pointing Machine, Butt Welding Machine, Electric Control Panel, Mechanical Descaling Attachment, Pay-Off Stand, Continuous Coiling Device, Annealing Furnace, Chemical Boraxing / Phosphating Plant. |

| Consumables: Tungsten Carbide Wire Drawing Dies, Lubricant Powder, Die Polishing Paste & Pins. |

|

|

|

Auxiliary Equipment: Continuous Coiling Device (Dead Coiler) |

|

- To be fitted to the final block of continuous wire drawing

machines. |

|

Model: MCC-24 |

|

Specifications: |

| Model: | MCC-12 | MCC-22 | MCC-24 | MCC-32 |

| Diameter of Drum of Wire Drawing Machine: | 12" (305 mm) | 22" (550 mm) | 24" (610 mm) | 32" (810 mm) |

| Wire Diameter Range: | 0.7 to 1.9 mm | 1.6 to 2.6 mm | 1.6 to 3.2 mm | 3.2 to 5.5 mm |

| Motor: | 5 HP | 20 HP | 20 HP | 30 HP |

| Speed: | Fixed (Optional: Variable) | Fixed (Optional: Variable) | Fixed (Optional: Variable) | Fixed (Optional: Variable) |

| Net / Gross Weight: | 425 / 615 kg | 2000 / 2500 kg | 2000 / 2500 kg | 2500 / 3000 kg |

| Case Dimensions: | 1.5 x 1.1 x 2.1 m & 1.1 x 0.8 x 0.6 m | 1.7 x 1.3 x 2.5 m & 1.2 x 1.0 x 0.8 m | 1.7 x 1.3 x 2.5 m & 1.2 x 1.0 x 0.8 m | 1.9 x 1.5 x 2.8 m & 1.3 x 1.1 x 0.9 m |

| Shipping Volume: | 4 m3 | 7 m3 | 7 m3 | 10 m3 |

|

Model: MCC-12 |

|

VIDEO OF CONTINUOUS COILING DEVICE (DEAD COILER) |

| Auxiliary Equipment: Wire Pointing Machine |

|

- This machine is suitable for pointing different types of

materials like Mild Steel, High Carbon Steel, Aluminium, Copper, etc. - The pointing rolls are made of EN-31 material and are ground finished. They are driven by power as well as by hand. - The machine is mounted on 4 wheels, making it mobile and useful to serve several drawing machines |

|

|

Specifications: |

| Model: | WPM-10 | WPM-15 | WPM-20 | WPM-25 | WPM-25C |

| Roller Length x Diameter: | 100 x 70 mm | 150 x 98 mm | 200 x 98 mm | 250 x 110 mm | 250 x 110 mm |

| Wire Diameter Range: | 1 to 3 mm | 2 to 8 mm | 2 to 10 mm | 3 to 12 mm | 4 to 14 mm |

| Wire Material: | Ferrous & Non-Ferrous | Ferrous & Non-Ferrous | Ferrous & Non-Ferrous | Ferrous & Non-Ferrous | Non-Ferrous (Brass, Copper) |

| Motor (HP): | 1.0 | 3.0 | 3.0 | 5.0 | 7.5 |

|

Auxiliary Equipment: Pay-Off Stand |

|

|

|

|

- M. S. Fabricated, double hand movable system Pay-Off Stand. |

|

|

Specifications: |

| Model: | MPOF-2 | MPOF-3 | MPOF-4 | MPOF-5 |

| Total Capacity: | 2 Tons | 3 Tons | 4 Tons | 5 Tons |

| Capacity per Arm: | 1 Ton | 1.5 Tons | 2 Tons | 2.5 Tons |

|

Auxiliary Equipment:

Mechanical Descaling Attachment - Suitable to fit with the first block of the wire drawing machines to remove the scales from the inlet wire rod.

|

|

|

|

|

Auxiliary Equipment:

Electric Control Panel - Suitable for Multi Blocker Wire drawing machines. |

|

| Auxiliary Equipment: Butt Welding Machine |

|

|

|

Specifications: |

| Model: | MBWD-4 | MBWD-6 | MBWD-8 | MBWD-15 | MBWD-20 | MBWD-35 |

| Capacity: | 4 KVA | 6 KVA | 8 KVA | 15 KVA | 20 KVA | 35 KVA |

| Welding Range: | ||||||

| Mild Steel: | 1 to 2.6 mm | 1.2 to 4 mm | 2 to 6 mm | 3 to 12 mm | 5 to 14 mm | 8 to 16 mm |

| Aluminium: | 1 to 2 mm | 1.2 to 3 mm | 2 to 5 mm | 3 to 11 mm | 5 to 12 mm | 8 to 14 mm |

| Copper: | 1 to 2 mm | 1.2 to 3 mm | 2 to 5 mm | 3 to 11 mm | 5 to 12 mm | 8 to 14 mm |

| High Carbon Steel: | -- | -- | 2 to 4 mm | 3 to 10 mm | 5 to 11 mm | 8 to 12 mm |

|

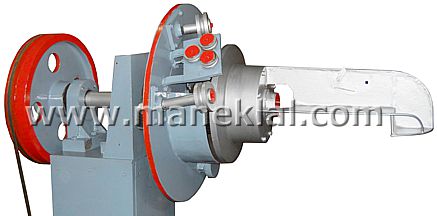

Auxiliary Equipment: Die Polishing Machine

- For polishing of Tungsten Carbide Wire Drawing Die Specifications:

|

|

|

Auxiliary Equipment:

Stripper / Spider - Unloading Stand for unloading drawn wires through overhead electric hoist |

|

|

Auxiliary Equipment:

Wire

Annealing Furnace:

Features: |

|

|

Specifications: |

| Model: | MWAF-0.6 | MWAF-1.0 | MWAF-1.2 | MWAF-1.5 | MWAF-2.0 |

| Capacity per Charge: | 0.6 Tons | 1.0 Tons | 1.2 Tons | 1.5 Tons | 2.0 Tons |

| Power Load: | 30 kW | 48 kW | 48 kW | 72 kW | 72 kW |

| Working Diameter: | 3.5 feet | 3.5 feet | 3.5 feet | 3.5 feet | 3.5 feet |

| Working Height: | 3.5 feet | 5.0 feet | 5.0 feet | 7.0 feet | 7.0 feet |

| Overall Diameter: | 6.5 feet | 6.5 feet | 6.5 feet | 6.5 feet | 6.5 feet |

| Overall Height: | 5.5 feet | 6.5 feet | 6.5 feet | 9.0 feet | 9.0 feet |

|

|

|

VIDEO OF WIRE ANNEALING FURNACE |

|

Horizontal Wire Drawing Machines: |

|

|

Features: |

|

|

| Diameter of Drum: | 30" to 47" (760 to 1200 mm) |

| Inlet Wire Rod Diameter: | 12 to 25 mm |

| Finished / Drawn Wire Diameter: | 11 to 24 mm |

| Gear & Worm Distance: | 500 to 1200 mm |

| Gear & Worm Ratio: | 1 : 30 |

| Drum Speed: | 8 to 15 rpm |

| Motor: | 40 to 75 HP |

| Approximate Weight: | 2500 to 4000 kg |

|

Fine & Intermediate Wet Wire Drawing Machines: |

|

Features: |

|

General Specifications:

|

|

|

|

|

VIDEO OF WET WIRE DRAWING MACHINE |

|

Auxiliary Equipment: Bobbin Winding Machines: |

|

|

|

|

|

Specifications: |

| Model: | BOW-1 | BOW-2 | BOW-3 |

| Wire Diameter Range: | 1.6 to 2.6 mm | 1.6 to 2.6 mm | 1.6 to 1.7 mm |

| Inside Diameter (ID) of Bobbin: | 200 mm | 110 mm | 50 mm |

| Outside Diameter (OD) of Bobbin: | 300 mm | 150 mm | 120 mm |

| Height of Bobbin: | 150 mm | 50 mm | 50 mm |

| Motor: | 3 HP | 3 HP | 2 HP |

| Net / Gross Weight: | 250 / 375 kg | 200 / 275 kg | 150 / 200 kg |

| Case Dimensions: | 1.2 x 0.9 x 1.2 m | 1.1 x 0.9 x 1.1 m | 1.0 x 0.9 x 1.1 m |

| Shipping Volume: | 1.5 m3 | 1.2 m3 | 1.0 m3 |

| Standard Equipment: Electric Motor, Starter, Bobbin with removable flange. |

| Optional Equipment: Control Panel instead of starter, motorized decoiler. |

|

VIDEO OF BOBBIN WINDING MACHINE |

Typical Four

Blocker Continuous Bull Block Wire Drawing Plant

for Drawing up to 2 mm Nail Wire from 6 mm or 5.5 mm Input Rod

| Machines | |

| 1. | Wire Drawing Machine, having FOUR Blocks in Tandem: 24” Single Die Holder, Inlet Wire size 6 mm, Finished wire size 2 mm in multiple passes, with one 30 HP / 960 RPM, two 25 HP / 1440 RPM and one 20 HP / 1440 RPM electric motors |

| 2. | Wire Pointing Machine, with 3 HP / 960 RPM electric motor |

| 3. | 8 KVA Butt Welding Machine |

| 4. | De-Scaling Attachment, to be fitted on the first block (of 24” diameter) of the Wire Drawing Machine |

| 5. | Motorized Die-Polishing Machine with 0.5 HP electric motor |

| 6. | Automatic Electric Control Panel Board, suitable for the above quoted four blocks of the Wire Drawing Machine |

| 7. | Continuous Coiling Device (Dead Coiler), suitable to unload the finished wires from continuous wire drawing machine automatically, complete with 20 HP / 1440 RPM electric motor and accessories |

| 8. | Fabricated Body, Double Hand System Pay-Off Stand suitable to release wires from coil |

| Recommended Drawing Dies and other accessories | |

| 9. | 19 x 17 pallet size Tungsten Carbide Dies (50 nos.) |

| 10. | 17 x 15 pallet size Tungsten Carbide Dies (210 nos.) |

| 11. | Diamond Pins (20 nos.) |

| 12. | Norbide powder (300 gms.) |

| 13. | Diamond Paste (5 Tubes) |

|

We also Offer DRAW BENCHES / BAR DRAWING MACHINES - Kindly follow this link for details |

|

Maneklal Global Exports |

|

TO OUR PAGE ON SMALL SCALE INDUSTRY PROJECTS |