|

|

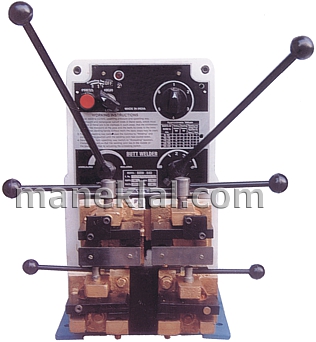

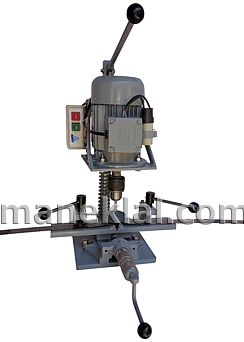

| Micro Butt Welders for Fine Wires |

|

Welding Process: - The ends of the wires to be joined are 'prepared' on the special shearing attachment (optional) - Welding current and initial up-set gap set according to the size of wire, the up-setting pressure being preset at works - The wire ends are rigidly clamped by special quick acting clamps and viewed through an illuminated magnifying glass (optional), to ensure correct alignment of the wire ends - By pushing the button, butt welding cycle is initiated and completed automatically by built-in controls - Weld completed, the job is then de-clamped and annealed in the annealing device (optional), if necessary

|

| Specifications: |

| Model: | MMBW-12 | MMBW-15 | MMBW-20 | MMBW-25 | MMBW-08C | MMBW-15C | MMBW-25C | MMBW-30C | MMBW-35C |

| Nominal Rating (KVA): | 1 | 1 | 1 | 1 | 1 | 1 | 3 | 4 | 5 |

| Input Volts: | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 400 |

| Frequency (Hz): | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Phase: | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 |

| Fuse Rating: | 6 | 6 | 6 | 6 | 6 | 6 | 13 | 13 | 16 |

| Shearing attachment for range diameter (mm) | 0.3 - 1.2 | 0.5 - 1.5 | 0.7 - 2.0 | 0.7 - 2.5 | 0.3 - 0.8 | 0.5 - 1.5 | 0.8 - 2.5 | 0.8 - 2.5 | 1.5 - 3.8 |

| Dimensions (mm): | 213 x 193 x 450 | 213 x 193 x 450 | 213 x 193 x 450 | 213 x 193 x 450 | 213 x 193 x 450 | 213 x 193 x 450 | 213 x 193 x 450 | 220 x 200 x 450 | 240 x 300 x 450 |

| Net Weight (Kg): | 15.5 | 15.5 | 15.5 | 15.5 | 15.5 | 15.5 | 20 | 20 | 35 |

| WELDING DATA | |||||||||

| Material to be welded: | Iron, Steel, Nickel | Iron, Steel, Nickel | Iron, Steel, Nickel | Iron, Steel, Nickel | Copper, Brass, Bronze, Aluminium | Copper, Brass, Bronze, Aluminium | Copper, HiCarbon, Aluminium, Mild Steel | Iron, Steel, Nickel, Copper, Brass, Aluminium, HiCarbon | Iron, Steel, Nickel, Copper, Brass, Aluminium, HiCarbon |

| Welding Range diameter (mm): | 0.3 - 1.2 | 0.5 - 1.5 | 0.7 - 2.0 | 0.8 - 2.5 | 0.3 - 0.8 | 0.5 - 1.5 | 0.8 - 2.5 | 1.0 - 3.0 | 1.5 - 3.8 |

| Wire Butt Welding Machine |

|

Welding Process: - The welding operation on these machines is automatic and the settings are easy - Electrode spacing is adjusted by a lever set against a plate calibrated for wire diameter - Upsetting pressure is adjusted by means of a dial calibrated for wire diameter - Welding current is selected by a rotary switch - Wires to be joined should be cut straight, exactly at right angles and free from burrs - Wire ends are clamped by spring loaded clamping device which can be opened singly or together by foot pedals - Releasing the foot pedals leaves the wire clamped under adequate pressure - By the push of the button, welding cycle is initiated and completed automatically by built-in controls - Weld completed, the job is then de-clamped and annealed if necessary in the separate annealing electrodes Features: |

|

|

Specifications: |

| Model: | MWBW-5 | MWBW-8 | MWBW-10 | MWBW-12 | MWBW-20 | |

| Max. Rating (KVA): | 5 | 8 | 10 | 12 | 20 | |

| Duty Cycle at Max. Rating: | 2% | 0.73% | 0.73% | 0.56% | 0.45% | |

| Input Volts: | 400 | 400 | 400 | 400 | 400 | |

| Frequency (Hz): | 50 | 50 | 50 | 50 | 50 | |

| Phase: | 1 | 1 | 1 | 1 | 1 | |

| Fuse Rating: | 10 | 10 | 10 | 15 | 15 | |

| Net Weight with movable stand: | 57 | 64 | 64 | 64 | 64 | |

| Dimensions with movable stand (mm): | 915 x 685 x 1120 | 915 x 685 x 1120 | 915 x 685 x 1120 | 915 x 685 x 1120 | 915 x 685 x 1120 | |

| WELDING DATA | ||||||

| Material to be welded: | Iron, Steel | Alloy Steel and Carbon Steel | Alloy Steel and Carbon Steel | Copper, Brass | Light Alloys | |

| Welding Range - wire diameter (mm): | Steel with less then 0.5% C, unalloyed | 2 - 8 | 2 - 8 | 2 - 10 | 1 - 5 | 3 - 8 |

| Steel with 0.5 to 1% C, alloyed | -- | 2 - 8 | 2 - 8 | -- | -- | |

| Copper | 2 - 3 | -- | -- | 1 - 4 | 2.5 - 6 | |

| Aluminium Light Metal | 3 - 5 | -- | -- | 1.5 - 6 | 4 - 7 | |

|

|

|

|

|

|

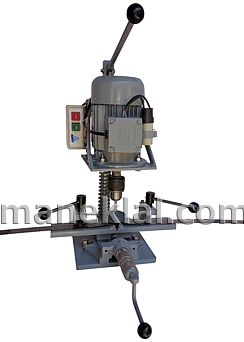

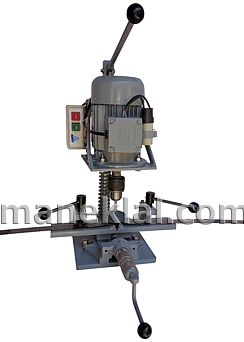

Model: MWBW-8 with Optional: Grinder |

Model: MWBW-8 with Optional: Grinder & Vice |

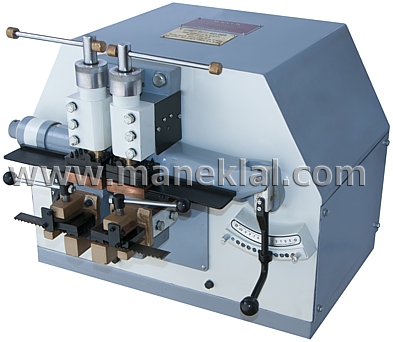

| Upset Butt Welding Machine |

Model: MUBW-20 |

Application: - Suitable for upset but welding of all profiles of wires and flats of iron, steel, alloy and carbon steel, copper, aluminium, brass and other light metals and their alloys Features: |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

| Rod Butt Welding Machine & Carbon Steel & Bimetal Blade Butt Welding Machine |

|

Application: Upset butt welding of all profiles of wires and flats of iron, steel, alloy and carbon steel, copper, aluminium, brass and other light metals and their alloys. Carbon Steel and Bimetal Blades Butt Welding Users: Include but not limited to wire strip and rod drawing mills, transformer motor and switch gear manufacturers, bandsaw and hacksaw blade users, small tool makers for welding mild steel shanks to alloy steel portion of taps, drills, bits, screw drivers, chisels, etc., hoop and ring manufacturers, wire forming industries, cable industries, automobile industries, air-conditioner and refrigerator makers, office equipment makers, etc.

Features: |

|

Simple Settings: 1. ELECTRODE SPACING: Adjust lever on indexing plate 2. WELDING CURRENT: Operate knob of the 8 step switch, current making and breaking is automatic via a built-in electromagnetic contactor 3. UPSETTING PRESSURE: Micrometrically adjustable with pressure knob 4. CURRENT ON / OFF: Micrometrically adjustable with simple thimble

Welding Process: |

|

|

| Specifications: |

| Model: | MRBW-15 | MRBW-20 | MRBW-25 | MRBW-30 | MRBW-40 | MRBW-50 | MRBW-60 | MRBW-75 | MRBW-100 | MRBW-150 |

| Max. Rating (KVA): | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 75 | 100 | 150 |

| WELDABLE MATERIAL | ||||||||||

| Mild Steel (diameter mm): | 3-12 | 4-14 | 5-16 | 6-17 | 8-18 | 10-20 | 16-22 | 18-25 | 19-28 | 20-31 |

| High Carbon Steel (diameter mm): | 3-9 | 4-11 | 5-12 | 6-13 | 7-14 | 8-15 | 10-16 | 12-17 | 12-18 | 13-20 |

| Copper (diameter mm): | 3-7 | 4-8 | 5-9 | 6-10 | 7-11 | 8-12 | 10-14 | 12-15 | 12-18 | 13-20 |

| Brass (diameter mm): | 4-9 | 5-10 | 6-11 | 7-12 | 8-13 | 8-14 | 10-16 | 12-17 | 13-19 | 14-22 |

| Aluminium (diameter mm): | 4-9 | 5-10 | 6-11 | 7-12 | 8-13 | 8-14 | 10-16 | 12-17 | 13-19 | 14-22 |

| Carbon Steel Blade (width mm): | 20-40 | 30-50 | 30-60 | 35-75 | -- | -- | -- | -- | -- | -- |

| Bimetal Blade (width mm): | 5-27 | 20-37 | 25-41 | 30-45 | 35-50 | 35-60 | 40-65 | -- | -- | -- |

| Fuse (Amps): | 30 | 40 | 50 | 75 | 100 | 125 | 150 | 180 | 250 | 375 |

| Machine Duty Cycle: | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% |

| Dimensions (mm): | 775 x 525 x 1050 | |||||||||

|

|

| Rod Butt Welding Machine - Pneumatically Operated with Thyristorised Electronic Timer |

|

Application: Upset butt welding of all profiles of wires and flats of iron, steel, alloy and carbon steel, copper, aluminium, brass and other light metals and their alloys. Carbon Steel and Bimetal Blades Butt Welding Users: Include but not limited to wire strip and rod drawing mills, transformer motor and switch gear manufacturers, bandsaw and hacksaw blade users, small tool makers for welding mild steel shanks to alloy steel portion of taps, drills, bits, screw drivers, chisels, etc., hoop and ring manufacturers, wire forming industries, cable industries, automobile industries, air-conditioner and refrigerator makers, office equipment makers, etc.

Features: |

|

| Specifications: |

| Model: | MRBW-15P | MRBW-20P | MRBW-25P | MRBW-30P | MRBW-40P | MRBW-50P | MRBW-60P | MRBW-75P | MRBW-100P | MRBW-150P |

| Max. Rating (KVA): | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 75 | 100 | 150 |

| WELDABLE MATERIAL | ||||||||||

| Mild Steel (diameter mm): | 3-12 | 4-14 | 5-16 | 6-17 | 8-18 | 10-20 | 16-22 | 18-25 | 19-28 | 20-31 |

| High Carbon Steel (diameter mm): | 3-9 | 4-11 | 5-12 | 6-13 | 7-14 | 8-15 | 10-16 | 12-17 | 12-18 | 13-20 |

| Copper (diameter mm): | 3-7 | 4-8 | 5-9 | 6-10 | 7-11 | 8-12 | 10-14 | 12-15 | 12-18 | 13-20 |

| Brass (diameter mm): | 4-9 | 5-10 | 6-11 | 7-12 | 8-13 | 8-14 | 10-16 | 12-17 | 13-19 | 14-22 |

| Aluminium (diameter mm): | 4-9 | 5-10 | 6-11 | 7-12 | 8-13 | 8-14 | 10-16 | 12-17 | 13-19 | 14-22 |

| Carbon Steel Blade (width mm): | 20-40 | 30-50 | 30-60 | 35-75 | -- | -- | -- | -- | -- | -- |

| Bimetal Blade (width mm): | 5-27 | 20-37 | 25-41 | 30-45 | 35-50 | 35-60 | 40-65 | -- | -- | -- |

| Fuse (Amps): | 30 | 40 | 50 | 75 | 100 | 125 | 150 | 180 | 250 | 375 |

| Machine Duty Cycle: | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% |

| Dimensions (mm): | 900 x 800 x 1300 | 900 x 800 x 1300 | 950 x 850 x 1450 | 950 x 850 x 1450 | 1100 x 900 x 1500 | 1100 x 900 x 1500 | 1100 x 950 x 1500 | 1100 x 950 x 1500 | 1550 x 1050 x 1600 | 1550 x 1050 x 1600 |

| Shipping Volume (m3): | 1.0 | 1.0 | 1.2 | 1.1 | 1.5 | 1.5 | 1.6 | 1.6 | 2.6 | 2.6 |

|

|

|

|

|

| Butt Welding Machines for Band Saw Blades |

|

Welding Process:

Process for Annealing: The upsetting way

switch lever is now turned to annealing and the job is clamped again with the

extended jaw distance which comes in automatically on flipping the lever to

annealing position. Shearing Attachment (optional): Special shears with arrangement for mounting on the front of the machine are available Grinding Attachment (optional): Grinding attachment mounted on top of the machine is necessary for removing the welding flash |

Model: MBW-15B |

Model: MBW-18B (with optional Auto Annealer) |

|

Specifications: |

| Model: | MBW-3B | MBW-5B | MBW-12B | MBW-15B | MBW-18B |

| Job | Carbon Steel Band Saw Blades | Carbon Steel Band Saw Blades | Bi-Metal Band Saw Blades | Bi-Metal Band Saw Blades | Bi-Metal Band Saw Blades |

| Band Saw Blade Width (mm): | 3 to 25 | 5 to 35 | 12 - 31 | 12 - 41 | 30 - 45 |

| Band Saw Blade Thickness (mm): | 0.6 to 1.2 | 0.6 to 1.2 | 0.8 to 1.4 | 0.8 to 1.4 | 0.8 to 1.4 |

| Nominal Capacity (KVA): | 3 | 5 | 12 | 15 | 18 |

| Grinder (KVA): | 0.12 | 0.12 | 0.25 | 0.25 | 0.25 |

| Max. Current (Amps): | 13 | 18 | 28 | 32 | 40 |

| Duty Cycle at Max. Rating: | 5% | 5% | 5% | 5% | 5% |

| Net / Gross Weight (kg.): | 25 / 35 | 28 / 38 | 44 / 54 | 54 / 64 | 56 / 75 |

| Dimensions (mm): | 275 x 235 x 225 | 275 x 255 x 225 | 760 x 540 x 640 | 760 x 540 x 640 | 760 x 540 x 640 |

|

|

|

|

|

VIDEO OF BAND SAW BUTT WELDING MACHINE MODEL: MBW-18B with AUTO ANNEALER |

Model: MBW-3B (with optional Shearing & Grinding Attachments) |

Model: MBW-12B |

Model: MBW-15B |

Standalone Abrasive Cutter |

Optional Accessories:

1. Automatic Annealing Attachment (in lieu of

manual annealing) 2. Shearing Attachment: For cutting the

Band Saw Blades at 90o |

Standalone Grinding Attachment |

| Upset Butt Welding Machines for Band Saw Blades |

|

Application: - Suitable for upset butt welding of Carbon Steel and BiMetal Blades

Features: |

|

|

|

|

Specifications: |

| Model: | MUBW-20B | MUBW-25B | MUBW-30B | MUBW-40B | MUBW-50B | MUBW-60B |

| Max. Rating (KVA): | 20 | 25 | 30 | 40 | 50 | 60 |

| WELDABLE MATERIAL | ||||||

| Carbon Steel Blade (width mm): | 30-60 | 30-65 | 35-75 | -- | -- | -- |

| Bimetal Blade (width mm): | 20-37 | 25-41 | 30-45 | 35-50 | 35-60 | 40-65 |

| Fuse (Amps): | 40 | 50 | 75 | 100 | 125 | 150 |

| Machine Duty Cycle: | 10% | 10% | 10% | 10% | 10% | 10% |

| Dimensions (mm): | 775 x 525 x 1050 | 775 x 525 x 1050 | 775 x 525 x 1050 | 775 x 525 x 1050 | 775 x 525 x 1050 | 775 x 525 x 1050 |

|

|

Standalone Abrasive Cutter |

Optional Accessories:

Shearing Attachment: Standalone Abrasive

Cutter for cutting the Band Saw Blades at 90o |

Standalone Grinding Attachment |

| Flash Butt Welding Machines - Pneumatically Operated - for Band Saw Blades |

|

Application: |

|

Welding Process: |

|

|

Specifications: |

| Model: | MFBW-30 | MFBW-40 |

| Max. Rating (KVA): | 30 KVA | 40 KVA |

| WELDING CAPACITY: | ||

| Width of Bimetal Blade: | 27 - 54 mm | 41 - 65 mm |

| Thickness of Bimetal Blade: | 0.9 - 1.6 mm | 0.8 - 1.4 mm |

| Input Current: | 75 Amps | 100 Amps |

| Duty Cycle: | 10% | 10% |

| Net / Gross Weight: | 150 / 250 kg | 150 / 250 kg |

| Dimensions: | 1650 x 975 x 1500 mm | 1650 x 975 x 1500 mm |

|

|

Standalone Abrasive Cutter |

Optional Accessories:

Shearing Attachment: Standalone Abrasive

Cutter for cutting the Band Saw Blades at 90o |

Standalone Grinding Attachment |

| Band Saw Blades |

|

- Rolls of Carbon Steel Band Saw Blades

for cutting wood, plastics and low alloy steels - Rolls of Bimetal Band Saw Blades for cutting steel |

|

|

Carbon Steel Band Saw Blades: |

| Width x Thickness |

Standard Tooth Teeth per Inch (per 25 mm) |

Hook Tooth Teeth per Inch (per 25 mm) |

| 6.0 x 0.63 mm (1/4" x 0.025") | 10, 14, 18, 24 | 4, 6 |

| 10.0 x 0.63 mm (3/8" x 0.025") | 4, 6, 8, 10, 14, 18, 24 | 3, 4, 6 |

| 12.5 x 0.63 mm (1/2" x 0.025") | 6, 8, 10, 14, 18, 24 | 3, 4, 6 |

| 16.0 x 0.80 mm (5/8" x 0.032") | 6, 8, 10, 14, 18 | 3, 4, 6 |

| 20.0 x 0.80 mm (3/4" x 0.032") | 6, 8, 10, 14, 18 | 3, 4, 6 |

| 25.0 x 0.90 mm (1" x 0.035") | 4, 6, 8, 10, 14 | 2, 3, 4, 6 |

|

|

| Width x Thickness |

Standard Tooth Teeth per Inch (per 25 mm) |

Hook Tooth Teeth per Inch (per 25 mm) |

| 6.0 x 0.63 mm (1/4" x 0.025") | 8, 10, 14, 18, 24 | 4, 6 |

| 10.0 x 0.63 mm (3/8" x 0.025") | 8, 10, 14, 18 | 3, 4, 6 |

| 12.5 x 0.63 mm (1/2" x 0.025") | 6, 8, 10, 14, 18, 24 | 3, 4, 6 |

| 16.0 x 0.80 mm (5/8" x 0.032") | 10, 14, 18 | 4 |

| 20.0 x 0.80 mm (3/4" x 0.032") | 6, 8, 10, 14, 18 | 3, 6 |

| 25.0 x 0.90 mm (1" x 0.035") | 6, 8, 10, 14 | 2, 3, 4 |

|

|

| Width x Thickness | Constant TPI | Variable TPI |

| 13 x 0.60 mm | 10, 14, 18, 24 | 8/12, 10/14 |

| 13 x 0.90 mm | 10, 14, 18, 24 | 6/10, 8/12, 10/14 |

| 20 x 0.90 mm | 6, 10, 14 | 4/6, 5/8, 6/10, 8/12, 10/14 |

| 27 x 0.90 mm | 6, 10, 14 | 4/6, 5/8, 6/10, 8/12, 10/14 |

| 34 x 1.10 mm | 4, 6, 8 | 3/4, 4/6, 6/10, 8/12, 5/8 |

| 41 x 1.30 mm | 4, 6 | 3/4, 4/6, 8/12, 5/8 |

|

|

| Width x Thickness | Constant TPI | Variable TPI |

| 27 x 0.90 mm | -- | 2/3, 3/4, 4/6 |

| 34 x 1.10 mm | -- | 2/3, 3/4, 4/6 |

| 41 x 1.30 mm | -- | 2/3, 3/4 |

| 54 x 1.60 mm | -- | 2/3 |

| 67 x 1.60 mm | -- | 1.4/2, 2/3, 3/4, 0.75/1.25, 0.75/1.10 |

| 80 x 1.60 mm | -- | 1.4/2, 2/3, 3/4, 0.75/1.25, 0.75/1.10 |

|

Maneklal Global Exports |

|

TO OUR PAGE ON SMALL SCALE INDUSTRY PROJECTS |