|

|

|

|

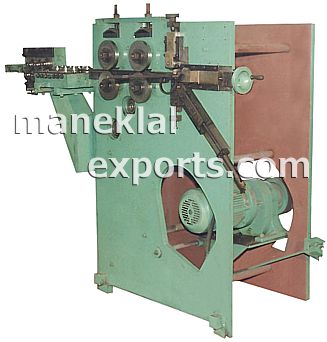

- Machine constructed from steel - Machine fitted with a number of rolls with forming dies on its end, through which a cut strip is passed - In a single pass, the desired strip is formed, suitable for making rolling shutters - Drive of the machine through machine cut gears - necessary guides and supports are provided for the strips to pass through rolls - Coil roll can be loaded - 6 Station Machine for making One profile, 7 Station Machine for making Two profiles, 8 Station Machine for making Three profiles of Rolling Shutter Strips / Slats |

Model: RSS-4.5 with 6 pairs of Rolls |

|

|

Specifications: |

| Model: | RSS-4.5/LD | RSS-4.5 | RSS-5.0/LD | RSS-5.0 | RSS-6.0/LD | RSS-6.0 |

| Capacity - Width of Strip: | 4.5" / 115 mm | 4.5" / 115 mm | 5.0" / 127 mm | 5.0" / 127 mm | 6.0" / 152 mm | 6.0" / 152 mm |

| Capacity - thickness of sheet (mm): | 0.4 to 0.9 | 0.7 to 1.2 | 0.4 to 0.9 | 0.7 to 1.2 | 0.4 to 0.9 | 0.7 to 1.2 |

| Capacity - Max. length: | no limit | no limit | no limit | no limit | no limit | no limit |

| Size of formed rolling strip (round type): | 3" / 76 mm | 3" / 76 mm | 3.35" / 85 mm | 3.35" / 85 mm | 3.75" / 95 mm | 3.75" / 95 mm |

| Number of Rolls: | 6, 7 or 8 pairs | 6, 7 or 8 pairs | 6, 7 or 8 pairs | 6, 7 or 8 pairs | 6, 7 or 8 pairs | 6, 7 or 8 pairs |

| Machine Speed (Feet / Minute): | 20 | 20 | 20 | 20 | 20 | 20 |

| Machine Speed (Meters / Minute): | 6 | 6 | 6 | 6 | 6 | 6 |

| Motor (HP): | 5 | 5 | 5 | 5 | 5 | 7.5 |

| Net / Gross Weight (kgs.): | 950 / 1300 | 950 / 1300 | 1100 / 1450 | 1100 / 1450 | 1200 / 1600 | 1200 / 1600 |

| Dimensions (m): | 2.0 x 1.4 x 1.1 | 2.0 x 1.4 x 1.1 | 2.2 x 1.5 x 1.2 | 2.2 x 1.5 x 1.2 | 2.5 x 1.6 x 1.4 | 2.5 x 1.6 x 1.4 |

| Shipping Volume (m3): | 4.0 | 4.0 | 5.0 | 5.0 | 6.0 | 6.0 |

Model: RSS-4.5 with 8 pairs of Rolls |

|

Common Profiles / Designs of Rolling Shutter Strips / Slats |

|

|

Model: RSS-6.0 with 7 pairs of Rolls to make DESIGN SLATS |

|

Model: RSS-5.0 with Optional: Abrasive Cutter |

|

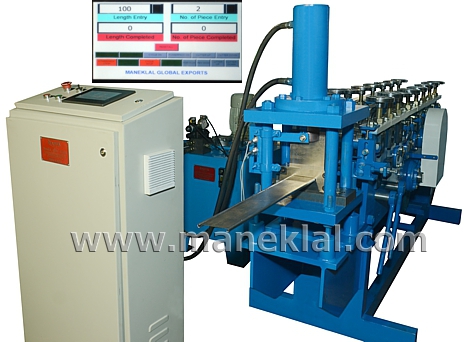

Model: RSS-6.0 with 8 pairs of Rolls and Optional: PLC Based Automatic Programmable Cutting System |

Model: RSS-6.0 with 8 pairs of Rolls and Optional: PLC Based Automatic Programmable Cutting System |

|

VIDEO OF OUR ROLLING SHUTTER STRIP / SLAT MAKING MACHINE MODEL: RSS-6.0 WITH SEVEN PAIRS OF ROLLS TO MAKE DESIGN SLATS |

|

VIDEO OF OUR ROLLING SHUTTER STRIP / SLAT MAKING MACHINE MODEL: RSS-6.0 WITH SIX PAIRS OF ROLLS TO MAKE SLATS WITH TWO VEINS |

|

VIDEO OF OUR ROLLING SHUTTER STRIP / SLAT MAKING MACHINE MODEL: RSS-4.5 WITH EIGHT PAIRS OF ROLLS TO MAKE 3 DESIGNS OF SLATS |

|

VIDEO OF OUR ROLLING SHUTTER STRIP / SLAT MAKING MACHINE MODEL: RSS-5.0 WITH OPTIONAL ABRASIVE CUTTER |

|

VIDEO OF OUR ROLLING SHUTTER STRIP / SLAT MAKING MACHINE MODEL: RSS-6.0 WITH EIGHT PAIRS OF ROLLS TO MAKE 3 DESIGNS OF SLATS, WITH OPTIONAL PLC BASED AUTOMATIC CUTTING SYSTEM |

|

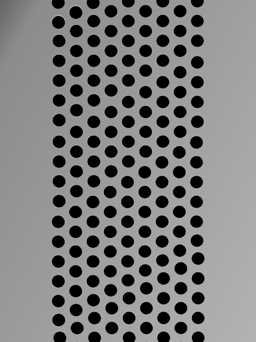

VIDEO OF OUR ROLLING SHUTTER STRIP / SLAT MAKING MACHINE MODEL: RSS-6.0/SS USING MICRO-PERFORATED STAINLESS STEEL STRIPS |

|

VIDEO OF OUR ROLLING SHUTTER STRIP / SLAT MAKING MACHINE MODEL: RSS-4.5/LD WITH SIX PAIRS OF ROLLS |

|

|

|

|

|

|

|

VIDEO OF OUR ROLLING SHUTTER STRIP / SLAT MAKING MACHINE MODEL: RSS-4.5 WITH SIX PAIRS OF ROLLS |

Model: RSS-4.5 with 8 pairs of Rolls |

Standard Accessories: Electric Motor, Starter, ‘V’ Belts, Coil Stand, One set of rolls

Optional Accessories:

|

Coil Stand |

|

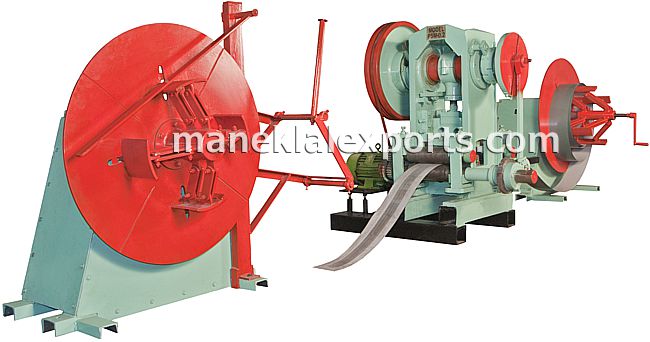

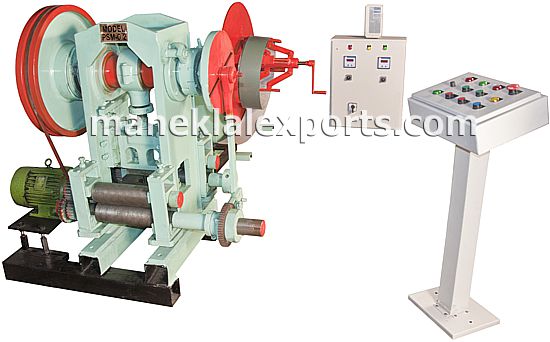

Model: PSM-0.2 |

|

Specifications: |

|

Model: PSM-0.2 |

|

VIDEO OF OUR MICRO-PERFORATING MACHINE MODEL: PSM-0.2 |

|

Standard Accessories: Main Machine: Electric Motor, Control Panel, Operation Panel, One pair of die for micro perforation of any one diameter above 3 mm De-Coiler: Electric Motor Coiler: Electric Motor and AC Drive Optional Accessories: Additional pair of dies for round or capsule shape perforation

|

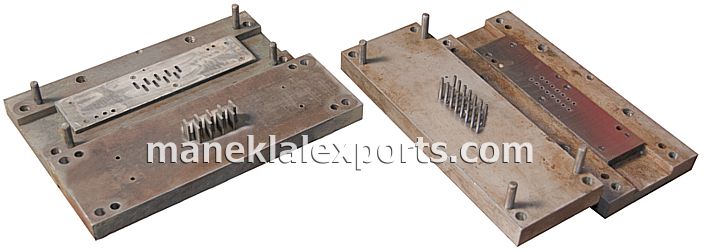

Perforating Dies |

|

|

- Machine constructed from

steel |

|

|

|

Specifications:

|

|

|

VIDEO OF OUR ROLL FORMING MACHINE TO MAKE GUIDES / 'U' CHANNELS MODEL: RFM-6.5/U |

|

Coil Stand of 3.5 ton capacity |

Standard Accessories: |

|

|

- Machine constructed from

steel |

|

|

|

Specifications:

|

Coil Stand of 3.5 ton capacity |

|

Standard Accessories:

Electric Motor, Starter, ‘V’ Belts,

Coil Stand, One

set of rolls for making 'L' Type Bottom Strip |

|

|

|

Specifications: |

|

Standard Accessories: Electric Motor, Gear Box, Starter, ‘V’ Belts, Coil Stand |

|

Maneklal Global Exports |

|

TO OUR PAGE ON SMALL SCALE INDUSTRY PROJECTS |