|

|

|

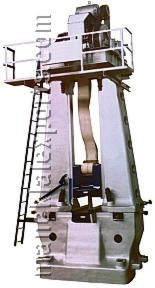

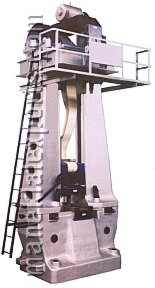

- Suitable for precision forging for the Automobile, Railways, Defense, Aeronautics, Hand Tools, Agricultural, Bicycle and other engineering industries -ANVIL BLOCK: Made of Grey Cast Iron weighing approximately 20 times the nominal capacity of the hammer. It is machined on both the top and bottom faces to hold die holder firmly and maintain position of the columns. Die holder fixed in the anvil block is forged from high grade alloy steel hardened and positioned properly with alloy steel tapered wedge - COLUMNS, SLIDES and TUP: Cast Steel columns, duly annealed and machined, positioned by a large spigot on the underside of each foot which fits into a machined recess in the anvil block. Columns locked with tapered wedges of alloy steel to ensure firm alignment of columns which helps in accurate grinding of tup (made of EN-9 cast steel). The clearance between the tup and guideways attached to columns maintained with the help of tapered wedge which brings the columns inward and the drawback bolt provided which pushes the columns outwards. Synthetic rubber mat provided on anvil block on which the columns rest. This dampens the induced shock vibrations, which increases the life of the tup and columns and also ensures smooth working of the machine for longer period. |

|

|

- GEAR HEAD: Heavy Duty Gear Head fabricated from rolled steel sections is mounted on top of the columns. Drive is through 'V' belts from high torque A.C. electric motor through flywheel and reduction gears to the lifter shaft. Friction lifting system fitted to the lifter shaft runs on double ball bearings and a central Phosphorous Bronze bearing. Friction lifter consists of constantly rotating drum and brake lined steel band. This band is anchored at one end to a stud in the lifter drum and the other end is carried by camshaft running through lifter drum, which is actuated by a lever. The lever is operated with the help of a pulling cord tied to the lever at one end and goes to operating point by passing through a capstan bush attached to the lifter shaft. When the cord is pulled, it tightens on to the rotating capstan bush, which operate the lever resulting in tightening of brake around the brake drum with the help of the camshaft. At this stage the lifter drum is rotated and tup is lifted with the help of a nylon belt. On release of the cord, the spring loaded arrangement helps free fall of the tup by disengaging friction band immediately from the friction drum. The spring loaded buffer works as a stopper for lifting drum in its rest position. Positive water cooling arrangement is provided to the friction drum to prevent excessive heating. |

|

Specifications: |

| Model: | FDH-300 | FDH-500 | FDH-750 | FDH-1000 | FDH-1250 | FDH-1500 | FDH-2000 | FDH-2500 | FDH-3000 |

| Size of Hammer (kg) | 300 | 500 | 750 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 |

| Weight of Tup (kg) | 300 | 500 | 750 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 |

| Space between slides (mm) | 360 | 432 | 495 | 542 | 575 | 620 | 670 | 727 | 800 |

| Stroke Maximum (mm) | 1450 | 1565 | 1630 | 1700 | 1700 | 1835 | 1835 | 1980 | 2100 |

| Max weight top die (kg): | 100 | 155 | 225 | 280 | 330 | 460 | 510 | 650 | 740 |

| Tup Front to Back (mm): | 330 | 400 | 430 | 490 | 520 | 550 | 610 | 660 | 700 |

| Total height of machine (mm) | 5000 | 5500 | 5590 | 6020 | 6300 | 6600 | 6750 | 7000 | 7250 |

| Max. number of blows per minute: | 45 - 95 | 44 - 90 | 40 - 82 | 36 - 75 | 36 - 75 | 32 - 66 | 32 - 66 | 30 - 62 | 25 - 56 |

| Max. weight of Job (kg): | 0.5 | 1 | 2 | 3 | 5 | 10 | 20 | 35 | 50 |

| Motor (HP): | 20 | 30 | 40 | 50 | 60 | 70 | 100 | 125 | 150 |

| Approximate Weight (kg): | 13000 | 21000 | 27000 | 34000 | 42000 | 50000 | 63000 | 71000 | 84000 |

| Standard Accessories: Electric motor and starter |

|

|

|

|

Maneklal

Global Exports |

|

TO OUR PAGE ON MACHINE TOOLS |