|

|

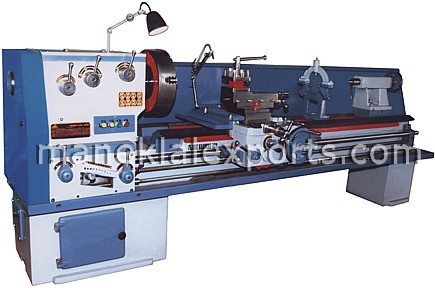

| Bench Lathe |

| - Close grained ground alloyed Cast Iron bed with hardness of

190 - 200 BH. - Totally enclosed dial type Gear Box with hardened and ground shafts running in Ball Bearing. - Spindles and Shafts ground and wearable parts standardized for interchangeability.  * Cabinet type Steel Stand & Tray seen above are Optional Accessories |

|

|

Standard Accessories:

1 HP Motor and Switch,

3-Jaw True Chuck (165 mm) with back Plate, 4 - Jaw Dog Chuck (200 mm) with back Plate,

Face and Centre Plates, 2 Centres, 2 Pt. traveling guide, threading dial and chart. |

|

- All gears are hardened and ground

Standard Accessories: Electric Motor, 3 and 4

jaw chuck, coolant pump, machine lamp, dead centre, dead centre sleeve, set of wrenches

and spanners, tool post and spindle key, chuck plate, starting shaft, face plate, steady

rest, follow rest and thread dial indicator. |

|

| - Spindle Cam lock type D1 - 4 Hardened &

Ground - Head stock gears, splines Hardened, Ground and Profile Ground - Head stock Lubricated by a built in Oil pump - Carriage, Surface Slide, Compound Slide & Tail Stock base of 25 Grad Casting, duly Stress Relieved - Taper Wages are of S. G. Iron in Surface slide & Compound slide - Apron Gears are Nitrated and made from EN 8 Material - Feed Box Gears are of EN 24 Material with Toughening Process - Four Position Tool Post with Heat treated Bolts - Tail Stock Spindle Hardened, Ground, Graduated on Outer Diameter with L. C. - End Gear train gears of 25 Graded Casting with bearing type Idler gear - Surface nut with Backlash Eliminator - All Dial Rings Hard chromed and least count Graduated. - Single Grounded Rack and Hardened & Ground Pinion - 2000 RPM in Spindle with two Speed Motor - All Screws made on CNC Turning Centers (Lead screw, Cross Slide screw, Compound Slide screw, Tail Stock screw) - Spindle instant stop electro plugging brake |

Model: 175 / 750 |

Model: 215 / 1000 |

| Model: | 175 | 215 | 250 | 254 | |

| Capacity | Height of Centre (mm): | 175 | 215 | 250 | 254 |

| Swing over Bed (mm): | 340 | 420 | 500 | 490 | |

| Swing over Cross Slide (mm): | 176 | 250 | 290 | 300 | |

| Distance Between Centres (mm): | 750 / 1000 | 1000 / 1500 | 1000 / 1500 | 1000 / 1500 / 2000 / 2500 / 3000 | |

| Max. Swing in Gap (mm): | 620 | 700 | 770 | 800 | |

| Bed | Bed Type: | 2V & 2 Flat | 2V & 2 Flat | 2V & 2 Flat | 2V & 2 Flat |

| Bed Width (mm): | 280 | 280 | 355 | 325 | |

| Length of Gap in front of Face Plate (mm): | 160 | 160 | 240 | 175 | |

| Headstock | Number of Spindle Speeds: | 8 | 8 | 18 | 8 |

| Spindle Speeds Range (rpm): | 54 to 1200 | 54 to 1200 | 32 to 1650 | 30 to 1230 | |

| Type and Size of Spindle Nose: | Cam lock size D1- 4 | Cam lock size D1- 4 | Cam lock size 6 | Cam lock size 6 | |

| Spindle Bore (mm): | 40 | 40 | 55 | 52 | |

| Spindle Morse Taper Number: | MT-5 | MT-5 | MT-6 | MT-6 | |

| Diameter of Front Bearing (mm): | 110 x 60 | 110 x 60 | 150 x 85 | 140 x 80 | |

| Tailstock | Spindle Diameter (mm): | 50.8 | 50.8 | 57.15 | 57.15 |

| Spindle Morse Taper Number: | MT-3 | MT-3 | 4 | 4 | |

| Spindle Travel (mm): | 175 | 175 | 200 | 200 | |

| Lateral Movement of Tailstock (mm): | 5 | 5 | 5 | 5 | |

| Saddle | Cross-slide Travel (mm): | 225 | 225 | 325 | 325 |

| Cross-slide Dimensions (mm): | 178 x 415 | 178 x 415 | 550 x 200 | 445 x 200 | |

| Compound Slide Traverse (mm): | 130 | 130 | 150 | 150 | |

| Saddle Traverse (mm): | 640 / 890 | 890 / 1390 | 890 / 1390 | -- | |

| Tool Shank Section (mm): | 22 x 22 | 25 x 25 | 25 x 25 | 25 x 25 | |

| Feeds and Threads | Number of Feeds: | 72 | 76 | 76 | 72 |

| Range of Longitudinal Feeds (mm/rev.): | 0.033 to 0.468 | 0.026 to 0.936 | 0.45 to 1.600 | 0.45 to 1.600 | |

| Range of Cross Feeds (mm / rev.): | 0.021 to 0.301 | 0.016 to 0.620 | 0.003 to 0.128 | 0.003 to 0.128 | |

| Number of Threads: | 103 | 106 | 106 | 103 | |

| Metric Range (number): | 0.2 to 6.5 mm (31) | 0.2 to 7.0 mm (33) | 0.2 to 7.0 mm (33) | 0.2 to 6.5 mm (31) | |

| Inch Range (number): | 72 to 4 TPI (36) | 72 to 4 TPI (36) | 72 to 4 TPI (36) | 72 to 4 TPI (36) | |

| D.P. Range (number): | 44 to 8 DP (21) | 44 to 8 DP (21) | 44 to 8 DP (21) | 44 to 8 DP (21) | |

| Module Range (number): | 0.4 - 3.0 MOD (15) | 0.3 - 3.0 MOD (16) | 0.3 - 3.0 MOD (16) | 0.4 - 3.0 MOD (15) | |

| Lead Screw Diameter (mm): | 31.75 | 31.75 | 31.75 | 38.1 | |

| Lead Screw Pitch (mm): | 6 | 6 | 6 | 6 | |

| Electricals | Main Motor (kW): | 1.5 | 2.25 | 3.75 | 2.25 |

Model: 250 / 1500 |

|

| Approximate Dimensions: |

| Model | Net Weight (kgs) | Gross Weight (kgs) | Case Dimensions (m) | Shipping Volume (m3) |

| 175 / 750 | 800 | 1000 | 2.1 x 1.0 x 1.3 | 2.70 |

| 175 / 1000 | 1000 | 1200 | 2.3 x 1.0 x 1.3 | 3.00 |

| 215 / 1000 | 1200 | 1400 | 2.3 x 1.0 x 1.5 | 3.50 |

| 215 / 1500 | 1300 | 1500 | 3.0 x 1.0 x 1.5 | 4.50 |

| 250 / 1000 | 1500 | 1700 | 2.8 x 1.0 x 1.5 | 4.20 |

| 250 / 1500 | 1800 | 2100 | 3.3 x 1.0 x 1.5 | 5.00 |

| 254 / 1000 | 1500 | 1775 | 2.7 x 1.1 x 1.4 | 4.20 |

| 254 / 1500 | 1850 | 2150 | 3.2 x 1.1 x 1.5 | 5.30 |

| 254 / 2000 | 2250 | 2550 | 3.8 x 1.1 x 1.5 | 6.30 |

| 254 / 2500 | 2400 | 2800 | 4.3 x 1.1 x 1.5 | 7.10 |

| 254 / 3000 | 2550 | 2900 | 4.8 x 1.1 x 1.5 | 8.00 |

|

Standard Accessories: Four Position Tool Post, Toolpost Spanner, Chuck Plate, Face

Plate, Centre Adapter, 2 x Dead Centres, Electric Motor with Electrical Controls, Thread

Dial Indicator, Steady Rest, Follow Rest, Chip Tray, 3 & 4 Jaw Chucks, Coolant Pump,

Machine Lamp With model 175, 215 & 250 only: Carrier Plate, Rear Splash Guard & Mechanical Brake Optional Accessories: Quick Change Tool Post, Taper Turning Attachment, Rear Tool Post, Keyway cutting attachment, Tool Post Grinder with 8" Grinding Wheel and electricals With Model 254 only: 12" Centre Height in lieu of the standard |

| Geared Head Heavy Duty Lathe with Norton Gearbox - "GHL" Series |

|

- Geared Head Heavy Duty Lathe with Norton Gearbox - Flame Hardened Bed  |

|

|

Standard Accessories: Face plate, Drive plate,

Steady rest, Follow rest, Thread dial indicator, 4-way tool post, one M.T. centre, 3 and 4

Jaw chuck, suitable motor with control panel, coolant pump and machine lamp. Optional Accessories: Taper Turning Attachment (Can be supplied only if ordered with the Lathe) |

|

Geared Head Heavy Duty Lathe with Norton Gearbox - "GH" Series |

|

- Geared Head Heavy Duty Lathe with Norton Gearbox - Flame Hardened Bed  |

|

Model: GH-12 |

|

|

|

Standard Accessories: Face plate, Drive plate,

Steady rest, Follow rest, Thread dial indicator, 4-way tool post, one M.T. centre, 3 and 4

Jaw chuck, suitable motor with control panel, coolant pump and machine lamp. |

|

Standard Accessories: Collet attachment with one Collet, Three step Spindle Pulley

bar feed, Toolbox, 2 HP Motor and Reversible Switch |

|

Standard Accessories: Collet attachment with one Collet, Toolbox, 2 HP

Motor and Reversible Switch and Coolant Pump |

|

|

Standard Accessories: Collet attachment with one Collet, Toolbox, 3 HP Motor, Panel Board, Pipe Bar feed Attachment, Automatic Feed for Cross Slide and Turret Slide by Self Shaft and Coolant Pump |

|

- Ideally suitable for economical production of precision

turned parts. - Wide range of materials like plastics, aluminium, free cutting steel, brass, etc. can be machined. - Cross slide rest with front and rear slides is included in the basic machine. - Tail stock is placed on the guide shafts and can be moved to and fro in the longitudinal direction. The feed motion is controlled by a drum cam. -Longitudinal turning attachment front can be optionally supplied for components which can not be produced by plunge cutting. This attachment is mounted on cross slides. The sliding movement of this attachment is controlled by a drum cam on the cam shaft. The radial motion is performed by a two pin lever. Thus stepped longitudinal operations can be made by utilizing two separate setting possibilities of the two cross movement or holding cams. Taper turning can also be done. |

|

|

|

|

Standard Accessories: Complete electrical equipment, bar feeding attachment, bar feed pipe,

double vertical slide, single open tool holder front & rear, automatic electric

shutter and a set of service tools Optional Accessories: Longitudinal Turning Attachment front, step turning tool holder, Collets - metric round (range 4 to 25 mm in steps of 0.5 mm), Drill Collets - metric (range 3 to 13 mm in steps of 0.5 mm) |

|

Maneklal

Global Exports |

|

TO OUR PAGE ON MACHINE TOOLS |